21

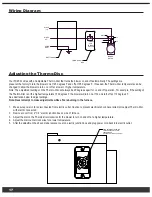

Problem: Down draft on chimney caused by one or more of the following.

• Cast iron damper in “CLOSED”

position.

• Open damper.

Possible Causes:

Remedies:

• Flue has a cold spot which

inhibits exhaust discharge from

rising properly.

• This problem may occur in factory built flues because the insulation

has settled or a seam has ruptured. In masonry flues, mortar loss

may be causing seepage of cooler outside air into the stack. Check

entire flue for structural integrity and leakage. Correct or repair as

needed, or replace or re-line the chimney.

• Remove obstruction.

• Increase chimney height.

• Open backdraft damper.

• There is an obstruction outside

chimney, such as a tree.

• Flue is located too close to the

peak of the roof or does not rise

above it to provide the proper

draft.

• Backdraft damper is in the

“closed” position.

9.

Problem: Odor detected in home during initial firing.

• There is an oily film that remains

on the steel after the manu-

facturing process. Firing the

furance has raised the tempera-

ture of the fire box to a level that is

sufficient to vaporize the residue.

• The odor should disappear after a few hours of usage.

Possible Causes:

Remedies:

10.

Problem: Excessive smoke discharge from fuel door during reloading.

Possible Causes:

Remedies:

• Cast iron damper in the

“CLOSED” position.

• Open damper.

• See #6.

• See #6.

• Too many elbows.

• Excessively long stove pipe run

from furnace flue.

11.

• See #6.

• See #9.

• Excessive smoke accumulation.

• Insufficient draft.