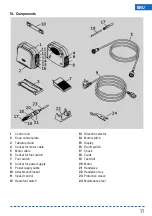

1. Field of application

The FINO Micromotor is a brush-free micromotor

suitable for all work in the dental lab or workshop. It

particularly excels in high performance and speed

stability. The control unit can either be used as

table top or knee controlled unit. If used as a tabletop

unit an additional foot switch for speed control can

be installed. The control unit is equipped with seve-

ral safety features to avoid any damage to the hand-

piece. All wearing parts are easily and economically

to replace.

2. Safety precautions

Safe operation and protection of the unit are only

ensured as long as it is used in compliance with spe-

cifications described in the user information using

only permitted tools. Additionally the following must

be observed:

• The directions of the manufacturer if the tools

• Never exceed the maximum allowed speed

of the tool in use

• Always wear eye protection and facemask

• The occupational safety regulations

• The accident prevention regulations

• Never operate the unit with moist hands!

If the safety precautions are not observed the hazard

of injuries for you and people in your surroundings

exists. FINO does not undertake any guarantee in

the case that these safety precautions are not obser-

ved!

3. Commencement of operation

Please check the unit for transportation damages

immediately after unpacking. All transportation

damages must be claimed promptly. Check the vol-

tage given on the type label of the unit and make

sure it corresponds with your mains supply.

3.1 Assembly

3.1.1 Tabletop unit

Danger of stumbling

Install all cables in a way that they do not

cause any occupational hazard. Place the con-

trol unit on an even and dry surface.

Push the knee-control plate 2

completely in and place the

tabletop stand 3 on the bottom

surface of the control unit.

Sub

sequently screw on the

tabletop stand 3 using the

included two screws. Place the

control unit on your workplace.

Now connect the plug of the

motor cable 5 with the socket 4

on the back of the control unit.

Thereby make sure that the

groove of the socket and the gap of the plug are

opposite each other. Tighten the nut firmly. Now you

connect the plug of the foot switch 7 with the socket

6. Also here the groove of the socket and the gap of

the plug must be opposite each other. Finally you

connect the power supply cable 9 with the power

supply socket 8. Put the control unit on the therefore

selected place on your workplace. Before you con-

nect the power plug with the mains socket check

again whether all cables are firmly connected to the

control unit.

3.1.2 Knee-control unit

Use only the included screws for

the fitting of the attachment

bracket. The use of other screws

could result in the damage of the

unit or your workbench.

We recommend in

stalling the

attachment bracket 10 in a height

of approx. 520-580 mm depen-

ding on your body height. Mark

the holes with a pencil.

Make sure that the attachment

bracket 10 is kept horizontally. If

necessary use a water level. Drill

the holes with a thin drill. Screw

the screws completely in to

ensure a frictionless installation

of the control unit.

3

ENU