5.6 Replacement of unit fuse

Remove the fuse holder using a flat blade driver.

Replace the damaged fuse with the spare fuse,

which is inside the fuse holder. Put the fuse holder

back. Order a new 250 V/3,15 A fuse.

6. Storage

Store thee unit in a dry and dust-free place.

7. Technical data

Control unit:

Voltage:

220 - 240 V; 50/60 Hz

Power consumption:

40 VA

Exterior dimensions:

W 94 x D 268 x H 228 mm

Weight:

2,9 kg

Handpiece:

Dimensions:

L 159 mm, ø 27 mm

Speed:

1.000 - 50.000 rpm

Cable length:

1,4 m

Weight:

230 g (without cable)

Foot switch:

Cable length:

1,8 m

Weight:

384 g

Tabletop stand:

Dimensions:

W 122 x D 268 x H 30 mm

Weight:

152 g

Handpiece tray:

Dimenstions:

W 60 x D 110 x H 45 mm

Weight:

68 g

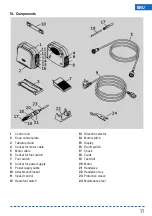

8. Delivery includes

Control unit, Tabletop stand, Motor hand

piece,

Motor handpiece tray, Foot switch, Attachment bra-

cket for control unit, Main tenance tools, Test drill.

9. Guarantee

Our technical recommendations of application are

based on our own experiences and tests and should

only be regarded as guidelines. It rests with the skills

and experience of the user to verify that the products

supplied by us are suitable for the intended proce-

dures. Our pro ducts are undergoing a continuous

further development. We reserve the right of chan -

ges in construction and composition. It is under -

stood that we guarantee the impeccable quality of

our products.

7

ENU

Test setting

Function

Test procedure

Sc

Switch

Test the function of the switch and its control light

by pressing the switches 12, 13 and 14.

dc

Display

All segments of the display are switched on one after the other.

Hc

Motor sensor

Turn the motor shaft to test the function of the motor sensors.

The display shows two bars in different heights.

Fc

Foot switch

Press the foot switch. The display shows 0-9 and A-F.

nc

Knee control plate

Press the knee-control plate. The display shows 0-9 and A-F.