MEGA SD - Cod.197DD8100

GB

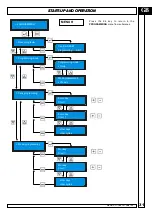

START-Up AND OpERATION

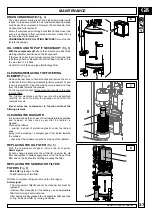

To RESET the warning messages, proceed as follows:

1) For messages relating to scheduled maintenance operations: carry out the operation and RESET component life.

Messages of this type are as follows:

- replace air filter.

- replace oil filter.

- replace oil.

- replace separator filter.

- replace dryer filter.

2) For critical operating condition messages:

If possible eliminate the problems the message will be cleared automatically.

Messages of this type are as follows:

- Compression temp. high

- Ambient temperature Iow

WArNING!!! If the warnings are not reset for aIong period of time (e.g. failure to carry out scheduled maintenance)

THE COMPrESSOr IS BLOCKED!!I In this case, contact the Service or Customer Centre of the Manufacturer

immediately.

•

Alarm messages

These messages indicate a serious fault that has blocked the compressor. The alarm may be due to a fault in the system or

extremely critical operating conditions.

When a machine stoppage occurs, the compressor stops immediately, the red LED L3 of the alarms

switche on and the message relating to the fault is displayed persistently in the main screen page.

The following faults block the machine: to rESET, first of ali eliminate the fault: at this point, LED-L3

starts to flash indicating that reseti can be carned out pressing the rESET key.

All faults that cause blocking of the compressor are saved in a error message log file, refer to paragraph 4.2.7.

The following faults block the machine:

- EMErGENCY STOP compress. - block

- Compression temp. too high - block

- Ambient temperature too Iow - block

- Internal pressure too high - block

- Net pressure too high - block

- Press Transducer error - block

- Temperature sensor error - block

- Power supply phase sequence error - block

- Short-cir. analog INPUT - block

- Compress. motor overload - block

- No. starts hr too high - block

- Power supply failure - block

- Line voltage cutoff - block

Faults caused by failure to carry out maintenance must also be added to these: if the compressor is used for long periods

without carrying out the scheduled maintenance indicated by the control unit, a machine blockage occurs accompanied by a

message of the type:

replace ---------------------- excess hrs - block

where the component to be replaced is displayed instead of the hyphens.

In this case, it is absolutely necessary to replace the component. If the compressor must be restarted, an emergency

start-up procedure must be carried out. Contact the Service or Customer Centre of the Manufacturer immediately.

To find out how to proceed in the case of an alarm, refer to chapter “Troubleshooting’.