11

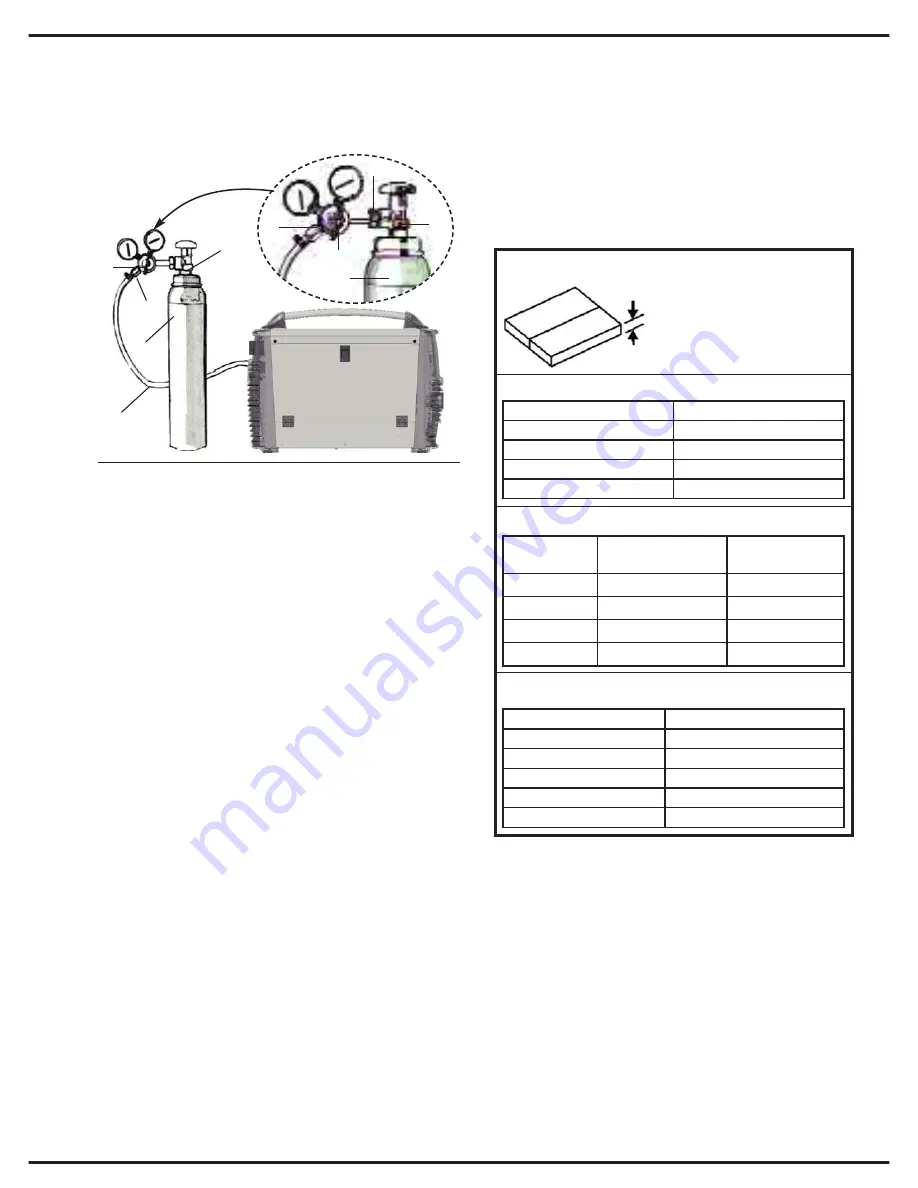

7. GAS CYLINDER AND GAS PRESSURE

REGULATOR CONNECTIONS

Only for MIG welding:

Skip this charter

entirely if the welder is to be used for MMA

Carefully follow the procedure shown

in Fig. 6:

Connect the pressure regulator (2) to the gas

cylinder (3). Tighten the bolt (6) between the reg-

ulator (2) and the cylinder (3). Do not overtighten

to avoid damaging the cylinder valve (1).

Connect the gas hose of the torch (4) to the

pressare regulator (2) and clamp securely

using a clasp (5). (Alternatively use cylinder

and hose fast connectors).

Connect the other end of the gas hose (6) to the

socket on the rear panel of the welder unit

(Fig.2 – 23), securing it with a clasp.

Connect the gas hose from the torch to the

appropriate socket (7) on the front panel of the

unit (fig 1 - 33), tightening clockwise. Do not

over-tighten.

Open the gas cylinder valve (1). Press the torch

button and check that gas is flowing through

correctly.

WARNING:

Cylinders contain high pressure

gas. Handle them with care. Inappropriate

treatment can cause serious accidents. Do not

pile gas cylinders up and never expose them to

excessive heat, flames or sparks. Do not bang

cylinders against each other. Contact your sup-

plier for more information regarding the use and

maintenance of gas cylinders.

WARNING:

Never use cylinders that are dam-

aged or show signs of oil or grease leakage.

Contact your supplier immediately of any such

circumstances.

8. WELDING METHODS

8.1 Manual MIG welding

To select this mode, turn knob 7 (Fig.1) to the

MIG MAN setting.

N.B.:

These are guidelines only and are to be con-

sidered applicable solely to workpieces no thicker

than 4mm. The settings are selected according to

wire diameter, location and welding gas.

Fig 7:

Current reference values, wire diameter,

wire speed and electronic inductance.

Proceed as follows for manual MIG welding:

1.

Set the welding current, according to the

thickness of the workpiece and the diameter of

the wire to be used, using the knob 10, Figure 1

(Step 1, Fig8). The display panel (Fig. 1 – 1)

shows the value selected.

2.

According to the diameter of the wire, set

the wire speed using knob 9 of Figure 1.

(Step 3, Fig.8)

3.

According to the kind of material, regulate the

electronic inductance (Fig. 1 – 8). (Step 4, Fig8)

4

3

2

1

6

2

5

1

3

5

Fig.6

Step 1:

Current selection

Convert the thickness of the

workpiece in to Amperes (A)

using the following formula:

0.025mm = 1A

i.e. 3mm = 125A

Step 2:

Wire diameter selection

Step 3:

Wire diameter selection

AMPERE (Min-Max)

WIRE DIAMETER

40-90 A

0,6mm

60-140A

0,8mm

80-160A

1mm

100-200A

1,2mm

wire diameter

recommended

wire speed

wire speed

0,6mm

1 amp ( 90mm/min) 90x120=11m/min

0,8mm

1 amp ( 50mm/min) 50x120=6m/min

1mm

1 amp ( 40mm/min) 40x120=5m/min

1,2mm

1 amp ( 30mm/min) 30x120=3,5m/min

Step 4:

Electronic inductance selection

Material

Electronic inductance setting

Ferrous materials (SG2 SG3)

min <~> med

Stainless steel (NI-Cr)

med

Aluminium (Al)

med <~> max

Copper-silicon (Cu-SI3)

med <~> max

Copper-aluminium (CU-Al8)

med <~> max

Содержание TM 215

Страница 1: ...Instructionsmanual TM215 ...

Страница 3: ......

Страница 4: ...1 6 5 A 2 2 2 5 V 1 4 0 A 2 5 6 V 1 2 0 A 2 4 9 V 3 1 1 V 1 7 2 V 2 0 5 V 1 3 0 A ...

Страница 6: ......

Страница 11: ......

Страница 12: ......

Страница 13: ......

Страница 14: ......

Страница 15: ......

Страница 16: ......

Страница 19: ......

Страница 24: ... NOTE ...

Страница 25: ... NOTE ...

Страница 26: ... NOTE ...

Страница 28: ......