6

Assembly

6.1

Safety

WARNING

Risk of Injury due to Unexpected Movement of Components

For vertical or slanted mounting position: when power is off, moving parts can

travel or fall uncontrolled into the lower end position.

• Bring moving parts of the product into a safe end position or secure them

against falling.

WARNING

Risk of injury due to unexpected movement of components.

The drive can move freely in the voltage-free state. This can cause unexpected

movements of the connected mechanics and crush parts of the body.

• Bring moving parts of the mechanical system into a safe position.

6.2

Unpacking

1. Open packaging.

2. Remove all transport materials (e.g. foils, caps, cardboard boxes).

3. Remove the product from the packaging and place it on the mounting surface.

4. Dispose of packaging and transport materials.

6.3

Mounting the cylinder

Requirement

–

No collision in the range of motion of the attachment component with mounting

components.

–

Flat mounting surface maximum 0.2 mm over the stroke length of the bearing

surface.

–

No distortion or bending when installing the product.

1. Select mounting attachments

2. Place the mounting attachments on the support points.

3. Tighten retaining screws.

Observe the maximum tightening torque and maximum screw-in depth.

For additional information, contact your local Festo Service.

Profile mounting

EAHF-L2

Direct fastening

EPCE, standard

EPCE-...-MB/-MD/-MF, Multimount

Mounting via profile

groove

Mounting via thread

Mounting via thread

Mounting via through-

hole

Tab. 2: Overview of mounting components

EPCE, standard

EPCE-...-MB/-MD/-

MF, Multimount

Size

45

60

45

60

Direct fastening via thread

Screw

M4

Max. screw-in depth t

max

[mm]

front, rear

15

14

top, bottom, left, right

–

8

Max. tightening torque

[Nm]

2.9

Centring (bore tolerance H7)

Centring sleeve

[mm]

–

Æ

7

Direct fastening via through-hole

Hole length

[mm]

–

34.6

38.6

Hole diameter

[mm]

–

4.5

Profile mounting EAHF-L2

Screw

Tab. 3: Information on mounting attachments

6.4

Mounting the attachment component

Torque on the Piston Rod

During commissioning and operation, the piston rod may only be operated

without torque.

If external torques occur, an external guide must be used.

Mounting the attachment component on the piston rod

When mounting the attachment component do not exceed the max. torque of the

piston rod. The max. torque of the piston rod may only be used for a short time

during mounting

Tab. 6 Information on attachment components.

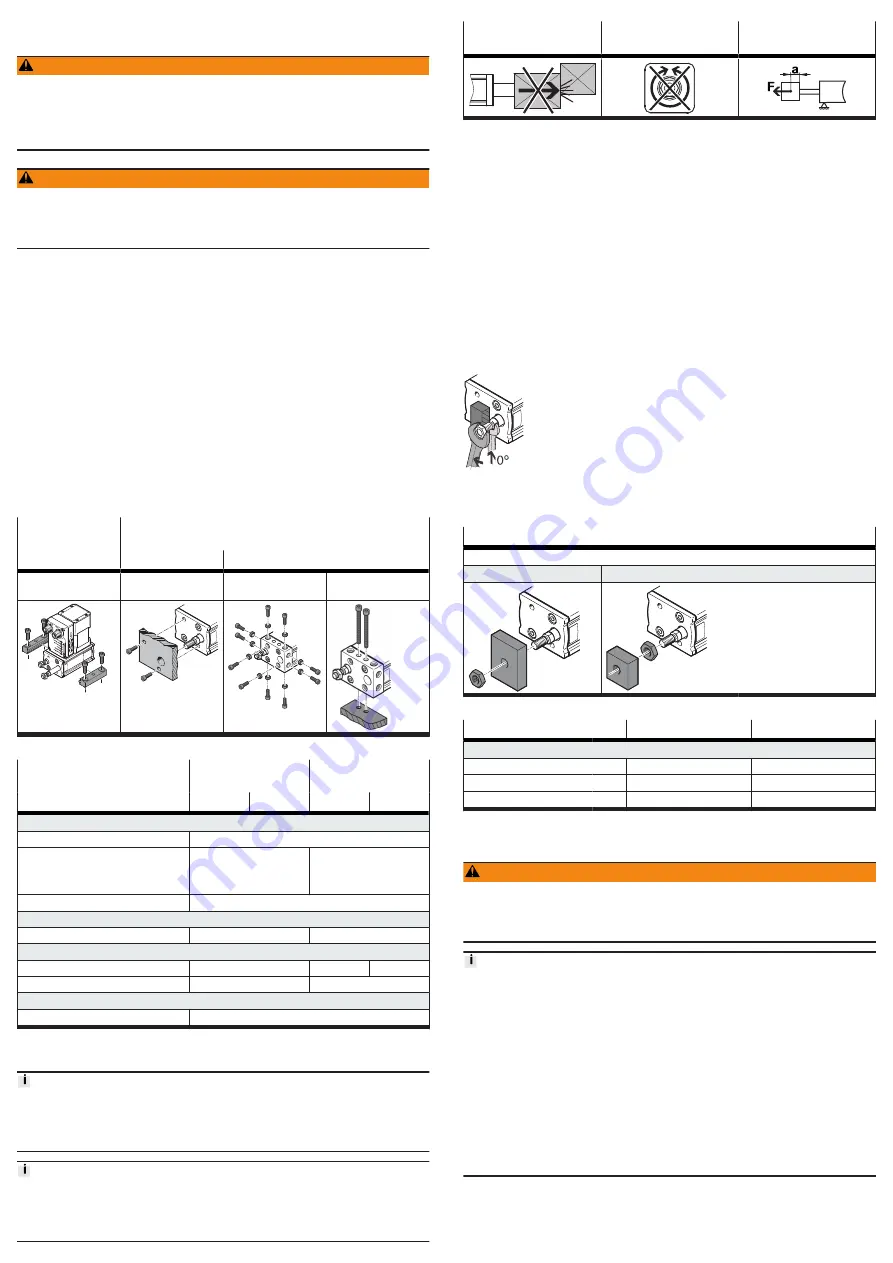

Collision-free

Torque-free

Centre of gravity and

tilting moment

Tab. 4: Requirement for attachment component

Requirement

–

No collision in the range of motion of the attachment component with mounting

components.

–

No transverse load or torque on the piston rod.

Absorb external forces and torques via an external guide.

–

Position of the centre of gravity and tilting moment (force F parallel to the axis

of movement) of the attachment component centred and close to the piston rod

(short lever arm a).

1. Select accessories

2. Screw the lock nut onto the male thread of the piston rod or attachment

component.

3. Rotate or place the attachment component on the piston rod.

4. Tighten lock nut.

The tightening torque must not act on the piston rod. Counterhold with a

suitable tool on the spanner flat of the piston rod.

Observe maximum tightening torque. The piston rod must not be turned.

Fig. 4: Torque-free mounting

When using an additional external guide, ensure that the electric cylinder and

piston rod are parallel and aligned exactly.

Direct fastening

Mounting via male thread

With nut

With lock nut

–

Rod eye SGS

–

Rod clevis SG

–

Coupling piece KSG

–

Self-aligning rod coupler FK

Tab. 5: Overview of attachment component

Size

45

60

Piston rod

Width across flats

ß

[mm]

7

10

Max. torque on the piston rod [Nm]

0.5

1

Nut, lock nut

M6

M10x1.25

Tab. 6: Information on attachment components

7

Installation

WARNING

Risk of injury due to electric shock.

• For the electrical power supply with extra-low voltages, use only PELV circuits

that guarantee a reinforced isolation from the mains network.

• Observe IEC 60204-1/EN 60204-1.

Damage to the device due to non-approved potentials at the pins

• Power connection:

• Do not connect pin 3

• Logic connection:

• EMCS-ST is not hot-pluggable. Only after connection of the reference poten-

tials GND/L– [Pin 4/8] can 24 V levels be applied to digital outputs DO1/DO2

[Pin 2/3] or the IO-Link communication signal C/Q [Pin 3].

• The DO1/DO2 [Pin 2/3] digital outputs and the IO-Link C/Q [Pin 3] communi-

cation signal must be disconnected 100 ms before the power supply connec-

tions GND/L– [Pin 4/8] and 24 V DC/L + [Pin 1], e.g. by the interposition of

relay contacts.

• GND and L– connections:

• The Power, GND [Pin 2] and Logic, GND/L– [Pin 4/8] connections must have

the same potential.

1. Connect cables to the [Logic] and [Power] connections of the integrated drive

EMCS-ST.

2. Connect cables to the controller or IO-Link master and to the PELV fixed power

supply units.