6.3

Mounting the motor

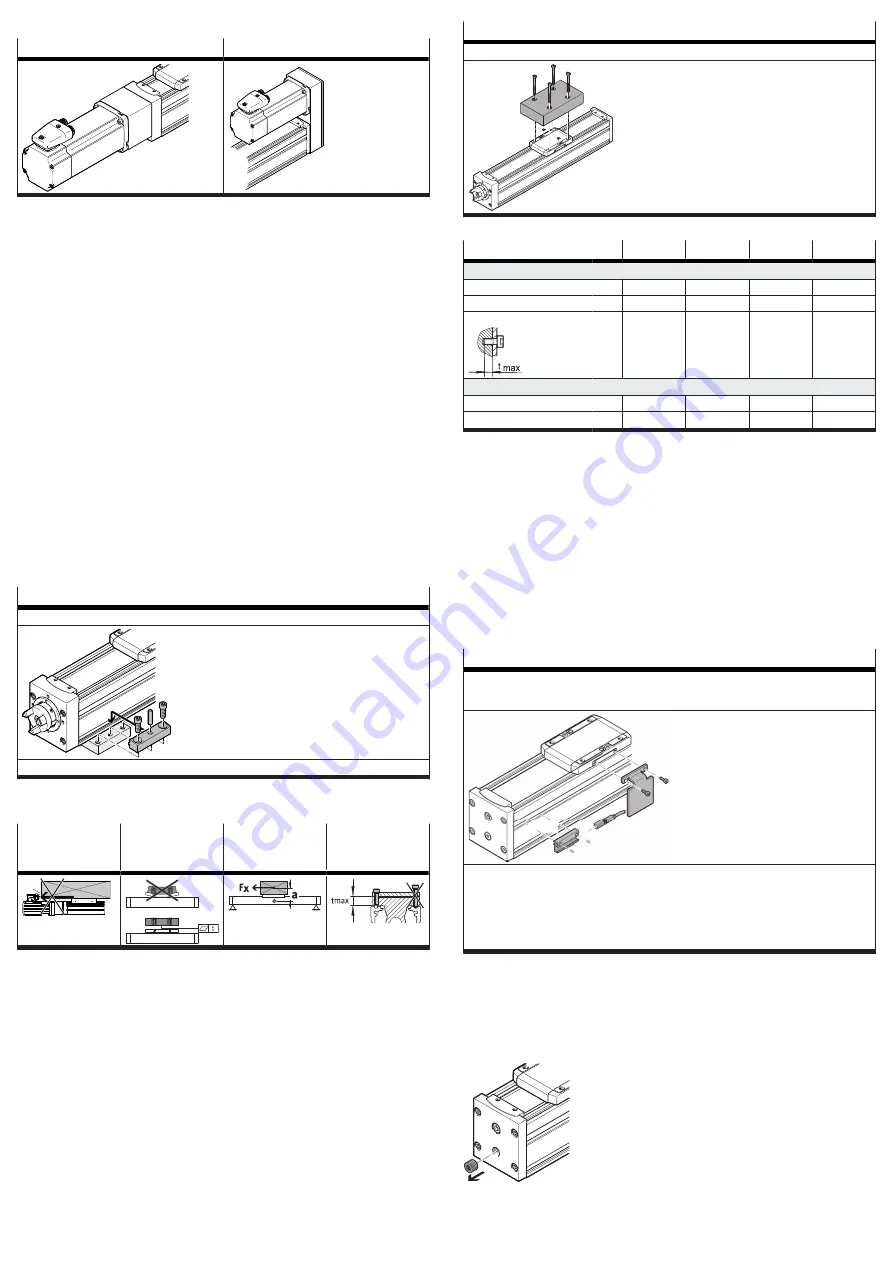

Axial kit EAMM-A

Parallel kit EAMM-U

Tab. 1: Overview of motor mountings

Only loosen screws or threaded pins that are described in the directions in the

instruction manual.

1. Select the motor and motor mounting kit from

Festo

When using other motors: observe the critical limits for forces, torques and

velocities.

2. Fasten motor mounting kit, observe instructions

3. Fasten the motor without tension. Support large and heavy motors.

Connect motor cables only on completion of mounting.

6.4

Mounting axis

Requirement

–

No collision in the movement space of the attachment component with motor,

mounting and sensor components.

–

Sufficient space to reach maintenance interfaces.

–

Sufficient space for reaching and securing the sealing air connection.

–

Flatness of the mounting surface of 0.05 %of the stroke length or maximum

0.5 mm over the stroke length of the bearing surface.

–

No distortion or bending when installing the product.

1. Select mounting attachments

2. Place the mounting attachments on the support points.

3. Tighten retaining screws.

Observe the maximum tightening torque and screw-in depth.

In the case of planar and 3-dimensional gantries, pay attention to parallelism,

product height and alignment of the axes.

For additional information, contact your local Festo Service.

Profile mounting EAHF-L2

Mounting via profile groove

Instruction manual

Tab. 2: Overview of mounting component

6.5

Mounting the attachment component

Collision-free

Flatness

Centre of gravity

and tilting

moment

Max. screw-in

depth

Tab. 3: Requirement for attachment component

Requirement:

–

No collision in the movement space of the attachment component with motor,

mounting and sensor components.

–

Flatness of the mounting surface of the attachment component of 0.01 mm

above the slide surface.

–

Minimise breakdown torque with force Fx. Short lever arm a from the centre of

the guide

to the centre of gravity of the attachment

–

The maximum screw-in depth of the retaining screws is not exceeded.

1. Select accessories

2. Place centring components in centring holes.

3. Position the attachment component on the slide.

4. Tighten retaining screws.

Observe max. tightening torque and max. screw-in depth.

When using an additional guide axis or external guide, ensure that the axes and

guide are aligned exactly parallel.

Recommendation: use guide mountings with tolerance compensation.

Direct fastening

Mounting via thread

Tab. 4: Overview of attachment component

Size

32

45

60

80

Direct fastening

Screw

M3

M4

M5

M6

Max. tightening torque

[Nm]

1.2

2.9

5.9

9.9

Max. screw-in depth t

max

[mm] 5.3

7.8

10.8

14.7

Centring (bore tolerance H7)

Centring pins

[mm]

Æ

2

Æ

4

–

–

Centring sleeve

[mm] –

–

Æ

5

Æ

7

Tab. 5: Information on attachment component

6.6

Mounting accessories

Requirement

–

No collision in the movement space of the attachment component with motor,

mounting and sensor components.

–

Protection against uncontrolled overtravel of the end positions.

–

Referencing to reference switch or end position.

–

Query of end positions or intermediate positions.

1. Select accessories

2. Mount the sensor (reference or query):

–

Mount the sensor bracket and switch lug (depending on the type of

mounting).

–

Mount the sensor.

Sensor bracket

–

Switch lug: mounting on slide

–

Sensor bracket: mounting via profile groove

–

Sensor: mounting on the sensor bracket

–

Protect the sensor from external magnetic or ferritic influences (e.g. min. 10 mm distance to slot

nuts).

–

Preferably use hardware limit switches with normally closed function (protection guaranteed even

in case of sensor failure).

–

Query switching lug only with inductive sensor.

–

Query integrated magnets in the slide only with magneto-resistive sensor.

Tab. 6: Overview of sensor mounting

Connecting sealing air

The use of overpressure or negative pressure in the range of approx. ± 0.02 MPa

(± 2.9 psi; ± 0.2 bar) reduces or prevents the following contamination:

–

The application of negative pressure minimises the release of abraded particles

into the environment.

–

Applying overpressure reduces the penetration of dirt into the drivetrain.

Fig. 3: Connecting sealing air

1. Remove the sealing air plug screw from the threaded hole.

2. Mount the screw fitting and connect the hose.