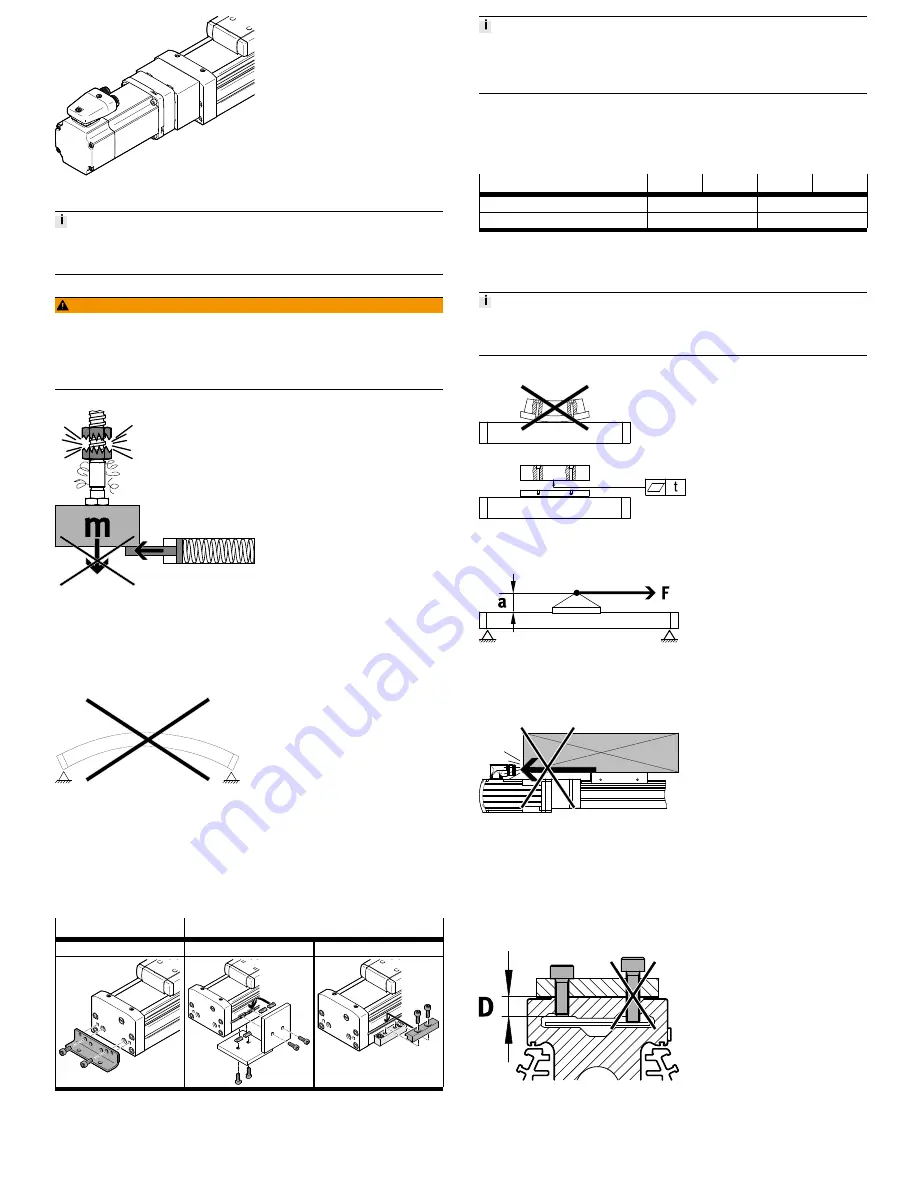

Fig. 4 Motor assembly

The reference position is lost when the motor is dismounted (e.g., when turning

the motor around).

•

Start homing

è

6 Commissioning.

Mounting position vertical or diagonal:

WARNING!

Risk of injury due to falling working loads.

In a power failure or if the spindle nut breaks, the working load may fall.

•

Only use motors with integrated spring-loaded holding brakes.

•

Implement external safety precautions to prevent the spindle nut from break-

ing (e.g. tooth clinking, moveable bolts or emergency buffers).

Fig. 5 Working load

Assembling the spindle axis

Prerequisites:

•

Position the spindle axis in such a way that its operating elements are access-

ible (e.g. relubrication openings).

•

Install spindle axis without tension or distortion.

Fig. 6 Assembly surface flatness

•

Fasten spindle axis to a mounting surface with flatness of 0.05% of the stroke

length, but max. 0.5mm. For gantry applications, attention must also be paid

to parallel alignment or product heights in alignment of the axes. For addi-

tional information, contact your local Festo Service

è

www.festo.com.

•

Take the required support clearances into consideration

è

9 Technical data: mechanical.

Interfaces for mounting components

On the cover

On the profile

e.g. with foot mounting HPE

e.g. with slot nuts NST

e.g. with profile mounting MUE

Tab. 2 Interfaces for mounting components

Danger of screws being pulled out if the spindle axis is only mounted to the cov-

ers and the torque load around the longitudinal axis is too great.

•

If there is high loading, mount the spindle axis on the profile with additional

mounting components.

1. Select mounting components

è

www.festo.com/catalogue.

2. Mount the mounting components outside the positioning range (avoid colli-

sions).

3. Mount the spindle axis.

4. Tighten the retaining screws evenly.

Size

70

80

120

150

Screw (cover)

M5

M8

Tightening torque

[Nm]

6

24

Tab. 3 Tightening torques of the retaining screws

Mounting attachments

Requirements

An uneven attachment component bends the slide and shortens the service life of

the guide.

•

Use an attachment component with an even surface. Evenness: t = 0.01 mm

Fig. 7 Evenness of payload

Fig. 8 Position the payload

•

Set down nominal load in such a way that the tilt moment resulting from force

F (parallel to the axis of movement) and lever arm are kept as small as pos-

sible

è

Fig.8.

Fig. 9 Protruding payload

•

Avoid collisions of the mounting part and payload with other mounting parts

è

Fig.9.

For attachment components with their own guide:

•

Adjust the guide and axis so that they are exactly parallel or use a connection

that permits tolerance compensation. This will prevent overloading of the

guide.

Mounting:

Fig. 10 Max. screw-in depth

•

Fasten the attachment to the slide with screws and centring sleeves. Observe

the maximum screw-in depth D and tightening torque

è

Tab. 4 Mounting the payload.