9.2

Checking axis elements

Checking toothed belt wear

The pretension of the toothed belt is designed for the entire service life.

Tensioning of the toothed belt is not permitted.

1. ELCC-...-PU1:

–

Initial check: after 1000 km.

–

Periodic check: every 500 km.

ELCC-...-PU2:

–

Initial check: after 5000 km.

–

Periodic check: every 1000 km.

2. If there is visible wear on the toothed belt: send the axis to Festo or contact

www.festo.comFesto Service.

Checking the cover strip (ELCC-...-70/90/110-P9 only)

•

Check: every 2000 km.

If waves form, the cover strip must be retensioned.

1

2

3

4

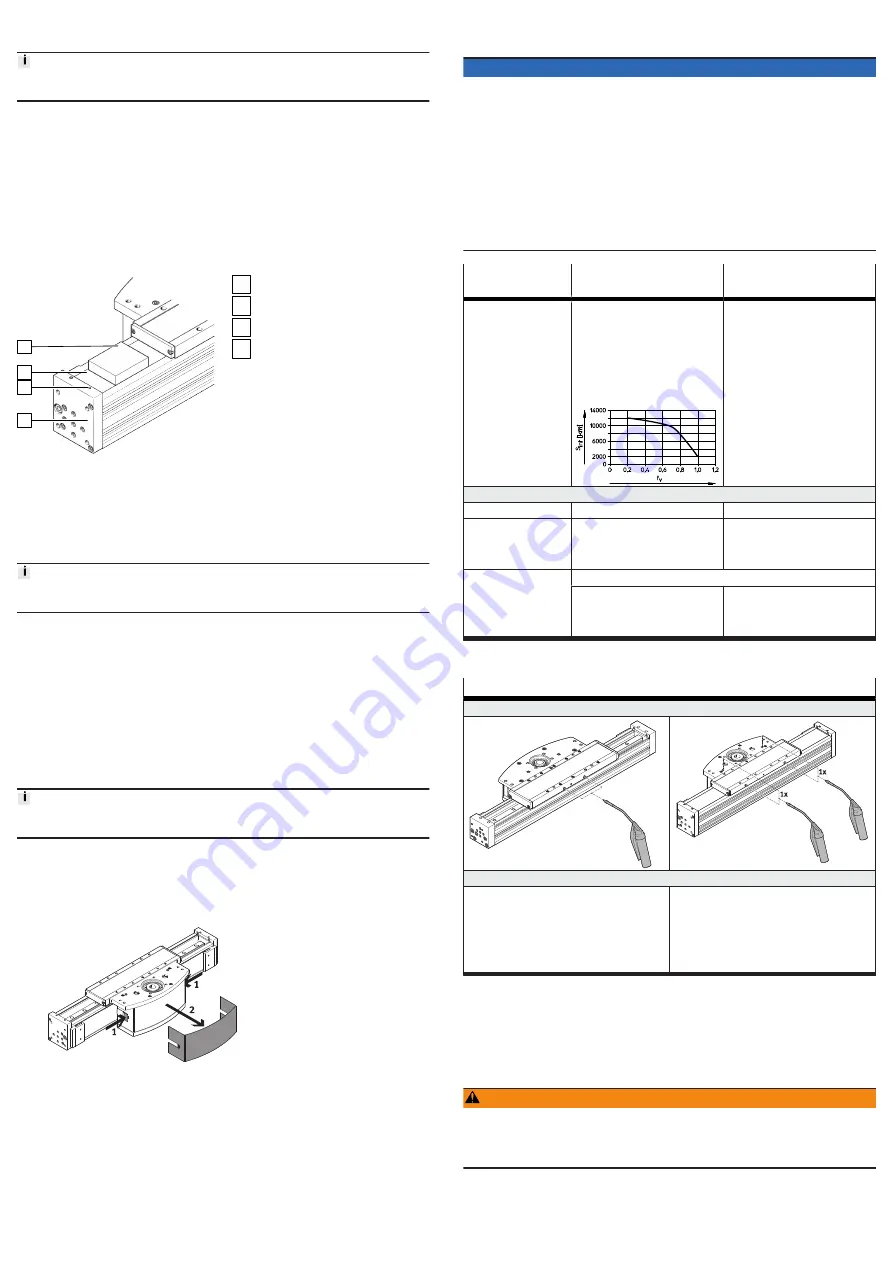

Fig. 6: Retensioning cover strip

1

Clamping element

2

Cover strip

3

Screw

4

End cap

Retensioning cover strip on both sides

1. Loosen screws

3

.

2. Push cover strip

2

into the end cap

4

.

3. Tighten cover strip with a clamping element

1

.

4. Tighten the screws.

Tightening torque: 6 Nm ±10 %.

If it is no longer possible to retighten the cover strip, the belt reversals and the

cover strip should be replaced

Clamping element

Checking clamping unit (ELCC-...-70/90/110-C only)

Check the holding force of the clamping unit at every maintenance interval or after

every emergency braking in the event of a power failure.

–

Check holding function as follows:

1. Move the cantilever or slide to an end position.

2. Exhaust the clamping unit connection

3. Allow the test force (the test pressure) to act on the drive for at least 5 s.

During this time, the cantilever or the slide must not move.

The test force and the tolerance window can be taken from the risk assess-

ment of the application.

The clamping unit must be replaced after 1000 emergency braking operations or

after 50,000 clamping operations

è

Contact your local Festo service centre.

9.3

Cleaning

Clean the product with a soft cloth. Do not use aggressive cleaning agents.

Removing abraded particles in the drive head

At every maintenance interval remove the particles from the toothed belt and

cover strip wear on the axis or in the drive head as required.

2. With the interlocks (1) pressed, pull the housing (2) off the drive head.

9.4

Lubrication

Lubrication interval and accessories

NOTICE

The lubrication interval S

int

is dependent on the load acting on the product.

Load factors include e. g.:

• Dusty and dirty environment

• Nominal stroke

>

2000 mm or

<

300 mm

• Speed

>

2 m/s

• Ambient temperature

>

+40 °C

• Service age of product

>

3 years

• Travel profile matches triangular operation (frequent acceleration and braking)

If one of these factors applies:

• Halve lubrication interval S

int

.

If several factors apply at the same time:

• Divide service interval S

int

by four.

Lubrication

Recirculating ball bearing

guide KF

Guide rail

Lubrication interval

–

Calculate the comparative

loading factor f

v

using the

formula for combined loads

–

Lubrication intervals S

int

as a

function of the load comparison

factor f

v

can be taken from the

diagram.

As required, e.g. if the grease layer

is insufficient.

Lubrication point

Lubrication hole

Interface

Lubricant

–

ELCC-TB-KF: roller bearing grease

LUB-KC1

–

ELCC-TB-KF-F1: Elkalub VP 874,

Chemie-Technik, Vöhringen

–

ELCC-TB-KF: roller bearing grease

LUB-KC1

Grease gun

Pressure grease gun with pinpoint nozzle LUB-1, 647958

–

Lubrication adapter, axial output,

LUB-1-TR-I, 647959

–

Lubrication adapter, radial

output, LUB-1-TR-L, 647960

–

Tab. 10: Overview of lubrication intervals and accessories

Lubricating guide

Recirculating ball bearing guide KF

Lubrication holes

Grease quantity per lubricating hole:

ELCC-TB-60 (size), 2 lubrication holes, inject

the specified weight of grease into both lubri-

cation holes at the front.

–

60: 1.7 g

ELCC-TB-70/90/110 (size), 4 lubrication holes,

inject the specified weight of grease into the

left and right of only one lubrication hole at the

front or top.

–

70: 5 g

–

90: 7.5 g

–

110: 11.2 g

Tab. 11: Lubrication overview

1. Inject lubricant into two lubrication holes.

2. During the lubrication process, travel the entire traverse path to distribute the

lubricant evenly inside the machine.

10

Malfunctions

10.1

Fault clearance

WARNING

Unexpected movement of components.

Injury due to impacts or crushing.

• Before working on the product, switch off the control and secure it to prevent it

from being switched back on accidentally.