–

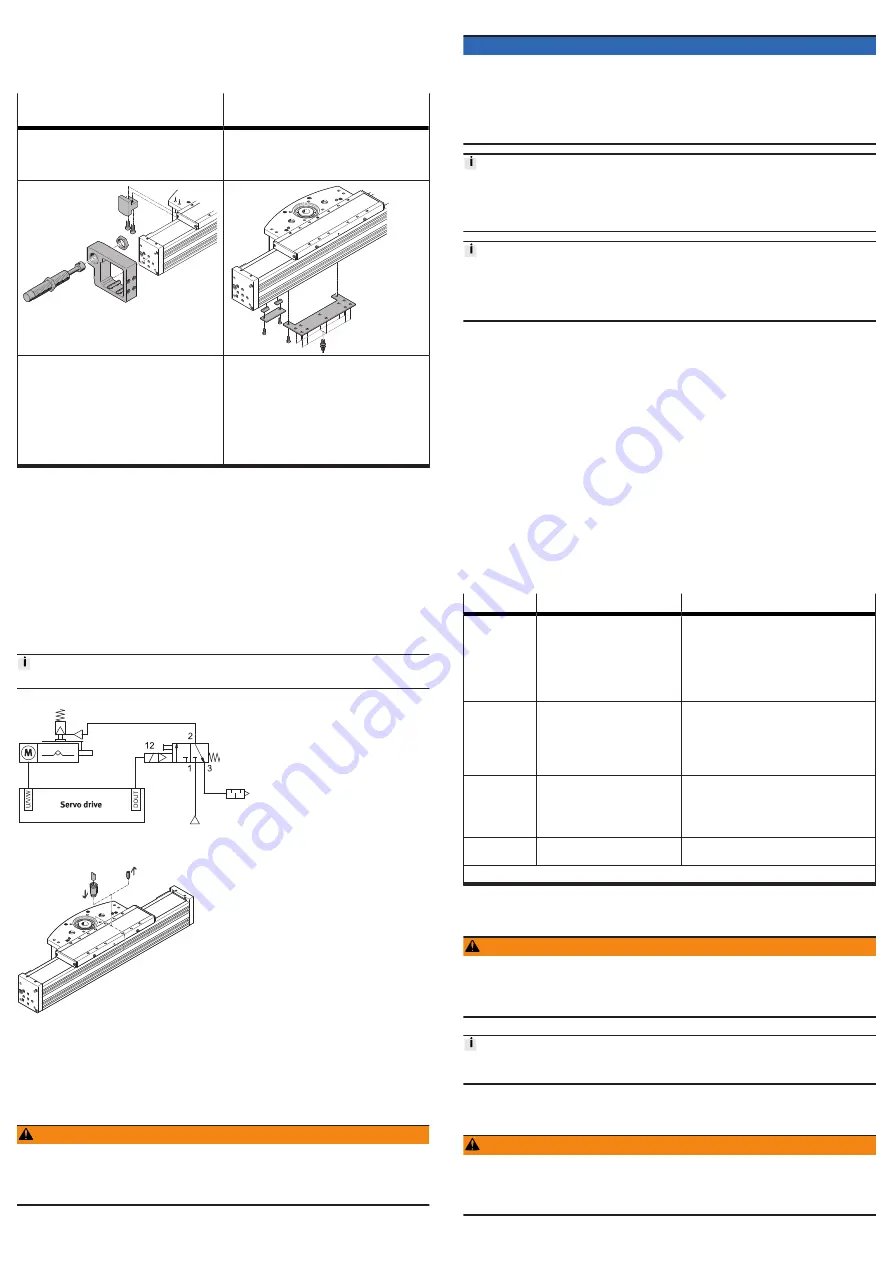

Mount sensor bracket and sensor.

–

Align and fasten the switch lug.

–

Fasten cable.

4. Mount the slot cover.

Instruction manuals

Shock absorber retainer and shock

absorber stop DAYP-E21

Sensor bracket and switch lug DASI-

E21

–

Shock absorber retainer: mounting via profile

groove

–

Shock absorber stop: mounting on the drive

head

–

Switch lug: mounting via profile groove

–

Sensor bracket: mounting on the drive head

Instruction manual

–

Protect the sensor from external magnetic or

ferritic influences (e.g. min. 10 mm distance

to slot nuts).

–

Preferably use hardware limit switches with

normally closed function (protection guaran-

teed even in case of sensor failure).

–

Query switching lug only with inductive

sensor.

Instruction manual

Tab. 8: Overview of shock absorber and sensor mounting

Connecting sealing air or clamping unit

The supply ports of the axis can be used as follows, depending on the product

variant:

–

Sealing air connection: for axes with strip cover ELCC-...-70/90/110-P9.

–

Clamping unit connection: for axes with attached clamping unit

ELCC-...-70/90/110-C.

The use of sealing air at approx. ± 0.02 MPa (± 2.9 psi; ± 0.2 bar) reduces or

prevents subsequent contamination:

–

The application of negative pressure minimises the release of abraded particles

into the environment.

–

Applying overpressure reduces the penetration of dirt into the drivetrain.

Always use Loctite 222 to seal an open supply port.

Fig. 4: Example of control of clamping unit ELCC-...-C

Fig. 5: Connecting sealing air or clamping unit

1. Remove one plug screw from the threaded hole of the slide or drive head.

2. Mount the fitting (M5; 0.5 Nm) and connect the tubing.

7

Commissioning

7.1

Safety

WARNING

Risk of injury due to unexpected movement of components.

• Protect the positioning range from unwanted intervention.

• Keep foreign objects out of the positioning range.

• Perform commissioning with low dynamic response.

7.2

Performing commissioning

NOTICE

Elasticity of the toothed belt

The elasticity of the toothed belt generates an additional spring effect at high

acceleration and deceleration, which can lead to an inadmissible nominal/actual

deviation when the slide is moved or when the end position is reached.

• Consider the setpoint deviation determined during the test run during parame-

terisation of position setpoint values.

When the motor is removed, the motor encoder loses its absolute reference to the

reference mark (e.g. by turning the motor drive shaft).

• Carry out a homing run after every motor mounting in order to establish the

absolute reference between the motor encoder and the reference mark.

Running noises during operation

Identically constructed axes can generate different running noises depending on

the parameterisation, mode of operation, type of mounting, installation environ-

ment and components.

Requirement:

–

Mounting of the drive system checked.

–

The protective cover of the cover strip is removed.

–

Installation and wiring of the motor checked.

–

No foreign objects in the movement space of the drive system.

–

Max. permissible feed force and drive torque not exceeded as a function of

acceleration, deceleration (e.g. stop function, quick stop), velocity, moving

mass and mounting position.

–

No mechanical overload of the axis and dynamic setpoint deviation not

exceeded (e.g. overrunning the end position) due to force and torque peaks

or overshoot effects.

Limit overloads and overruns by jerk limitation, lower acceleration and deceler-

ation setpoints or optimised controller settings.

–

Control and homing travel at reduced velocity, acceleration and deceleration

setpoint values.

–

No test run to mechanical end stops.

–

Software end positions do not lie within the effective range of the mechanical

stops.

Steps

Purpose

Note

1. Check travel

Determining the direction of

travel of the cantilever or slide

–

The direction of movement of the cantilever

or slide for positive and negative position

values depends on the mounting position

of the motor on the axis.

–

Set a required reversal of direction of rota-

tion via parameters in the servo drive or

controller.

2. Homing

Determination of the reference

point and adjustment of the

dimensional reference system

–

during the initial start-up pro-

cedure

–

after replacement of the motor

Permissible reference points:

–

towards reference switch.

Travel at reduced velocity

Further information

è

Instruction manual of

the drive system,

3. Test run

Checking the operating condi-

tions

Check application requirements:

–

Cantilever or slide runs through the com-

plete travel cycle in the specified time.

–

Cantilever or slide stops moving when a

limit switch is reached.

4. Test

clamping unit

Testing the holding force

After a successful test run, the drive system is ready for operation.

Tab. 9: Commissioning steps

8

Operation

WARNING

Risk of injury due to unexpected movement of components.

• Protect the positioning range from unwanted intervention.

• Keep foreign objects out of the positioning range.

• Perform commissioning with low dynamic response.

Test the holding function of the clamping unit after every emergency braking in

the event of a power failure

9

Maintenance

9.1

Safety

WARNING

Unexpected movement of components.

Injury due to impacts or crushing.

• Before working on the product, switch off the control and secure it to prevent it

from being switched back on accidentally.