Requirements for the connecting cable

Structure

Only use cables that ensure reinforced isolation

between the motor phases and the shielded sig-

nals of the holding brake and motor temperature

sensor in accordance with IEC 61800-5-1.

7.9.4 Shield support of the motor cable

Max. cable length

7.6 Information on EMC-compliant installa-

Max. capacitance

<

250 pF/m

Nominal cross section of power wires

1)

CMMT-AS-C7-11A-P3

2)

0.75 mm

2

…

1.5 mm

2

CMMT-AS-C12-11A-P3

3)

1.5 mm

2

…

2.5 mm

2

Cable diameter of the stripped cable or shield sleeve (clamping range of the shield clamp)

CMMT-AS-C7/C12-11A-P3

12 mm

…

17 mm

The only motor cables permitted are those that fulfil the requirements of EN 61800-5-2, Annex D.3.1

and the requirements of EN 60204-1.

1) Shield clamp and mating connector also permit larger cross sections.

2) for 0.75 mm² check that the shield diameter is sufficient for proper clamping

3) 2.5 mm² is recommended for cable lengths over 50 m to limit the voltage loss of the available output

voltage.

Tab. 31: Requirements for the connecting cable

Festo offers prefabricated motor cables as accessories

–

Only use motor cables that have been approved for operation with the Festo

servo drive. Motor cables of other manufacturers are permitted if they meet the

specified requirements.

7.9.2

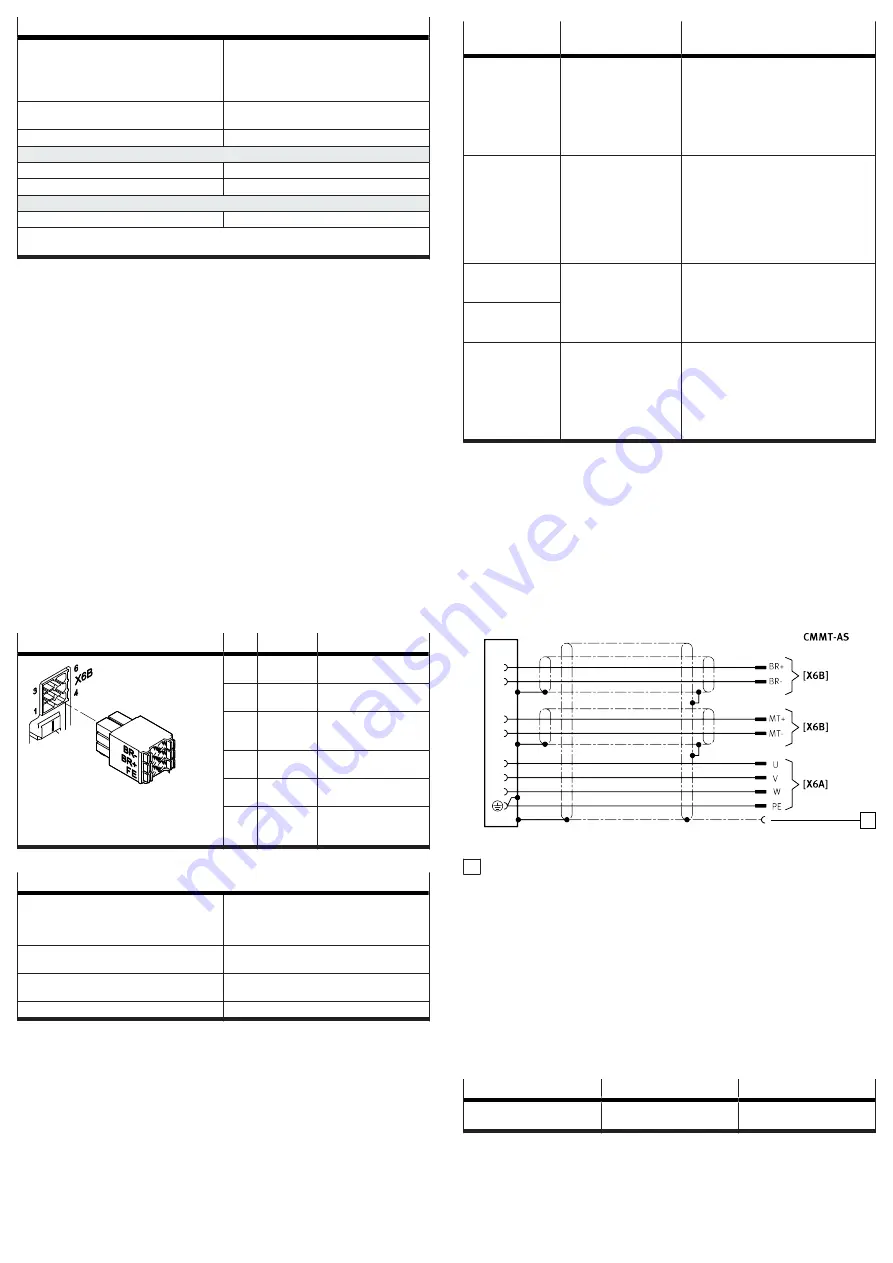

[X6B], motor auxiliary connection

The connection [X6B] is located on the front of the device. The holding brake

of the motor and the motor temperature sensor can be connected to the connec-

tion [X6B]. The output for the holding brake is used both functionally and in

connection with the safety sub-function Safe brake control

è

Manual Safety

sub-function.

To allow motor temperature monitoring, the following are supported:

–

N/C and N/O contacts

–

KTY 81 … 84 (silicon temperature sensors)

–

PTC (PTC resistor, positive temperature coefficient)

–

NTC (NTC resistor, negative temperature coefficient)

–

Pt1000 (platinum measuring resistor)

The servo drive monitors whether the motor temperature violates an upper or

lower limit. With switching sensors, only the upper limit value can be monitored

(e.g. with a normally closed contact). The limit values and the error response can

be parameterised.

[X6B]

Pin

Function

Description

6

MT–

Motor temperature (neg-

ative potential)

5

MT+

Motor temperature (posi-

tive potential)

4

FE

Functional earth con-

nected to protective

earth

3

BR–

Holding brake (negative

potential)

2

BR+

Holding brake (positive

potential)

1

FE

Functional earth con-

nected to protective

earth

Tab. 32: Motor auxiliary connection

Requirements for the connecting cable

Structure

–

2 wires for the line to the holding brake,

twisted in pairs, separately shielded

–

2 wires for the line to the temperature sensor,

twisted in pairs, separately shielded

Min. conductor cross section including wire end

sleeve with plastic sleeve

0.25 mm

2

Max. conductor cross section including wire end

sleeve with plastic sleeve

0.75 mm

2

Max. length

100 m

1)

1) Take voltage drop into account for cable lengths

>

25 m by selecting suitable cross-sections for the

insulated wires.

Tab. 33: Requirements for the connecting cable

Requirement for the temperature sensor in the motor

–

electrically reinforced isolation from the motor phases in accordance with

IEC 61800-5-1, voltage class C, overvoltage category III.

Shield support requirements

–

Connect the cable shield on both sides.

–

Make unshielded cable ends as short as possible (recommended 150 mm,

max. 200 mm).

7.9.3

Electronic overload and over temperature protection for the motor

The CMMT-AS allows the motor to be electronically protected against overload

and provides over temperature protection with the following protective functions:

Protective func-

tions

Description

Measures required during installa-

tion and commissioning

Temperature moni-

toring of the motor

The motor temperature is

monitored for an upper and

lower limit value, including

hysteresis. The limit values

can be parameterised.

–

Connect the temperature sensor to connec-

tion [X6B] (both switching and analogue

temperature sensors are supported)

–

Parameterise the temperature limit values

in accordance with the type of motor

used, e.g. using the device-specific plug-

in. Comply with the permissible limit

values of the motor.

Electronic current

limiting and I²t mon-

itoring of the motor

current

The motor current is

monitored electronically

and limited in accordance

with the limit values

specified in the standard

è

EN 61800-5-1, Tab. 29.

Motor currents and I²t time

constant can be parameter-

ised.

–

Parameterise the nominal current, max-

imum current and I²t time constant of the

motor, e.g. using the device-specific plug-

in.

Thermal memory in

the event of motor

switch-off

supported, cannot be para-

meterised

–

none

Thermal memory in

the event of a power

supply failure

Speed-sensitive over-

load protection

supported from firmware

version V019, parameteris-

able

–

Parameterise I²t monitoring with speed-

dependent scaling, e.g. with the device-

specific plug-in.

Such as for:

–

Synchronous servo motors (lower permis-

sible current at high rotational speed)

–

Fan motors (lower permissible current at

low rotational speed)

Tab. 34: Protective functions for the motor

The specified parameters are preset for Festo motors. The parameters can be

adapted in the plug-in.

7.9.4

Shield support of the motor cable

Requirements for the motor cable shield support on the device side

The type of shield support depends on the design of the motor cable. If,

for example, a hybrid cable is used to connect the motor, holding brake and

temperature sensor, the following options are available for connecting the shield

on the device side:

Option 1: all motor cable shields are jointly connected over a wide surface area

using a shield sleeve at the cable end and are connected below the shield clamp

on the front of the CMMT-AS.

1

Fig. 9: Shared shield support of all cable shields (example)

1 Shield sleeve

Option 2: the outside shield of the motor cable is connected separately over a

wide surface area below the shield clamp on the front of the CMMT-AS. The inside

shields are connected separately to the designated FE pin of the connection [X6B].

•

Make unshielded cable ends as short as possible.

Mounting the shield clamp

The lower section on the front of the housing is used as a shield support surface.

The shield support surface, together with the shield clamp, allows the motor cable

shield to be connected over a wide surface area

1. Using the shield clamp, press the motor cable shield or the conductive shield

end sleeve of the motor cable onto the shield support surface of the housing.

2. Tighten the retaining screws (2x) of the shield clamp with a size T20 TORX

screwdriver. Pay attention to the clamping range and observe the tightening

torque specified below.

Property

Value

Comments

Clamping range

12 mm … 17 mm

Diameter of the stripped cable

or shield sleeve