7.8.1

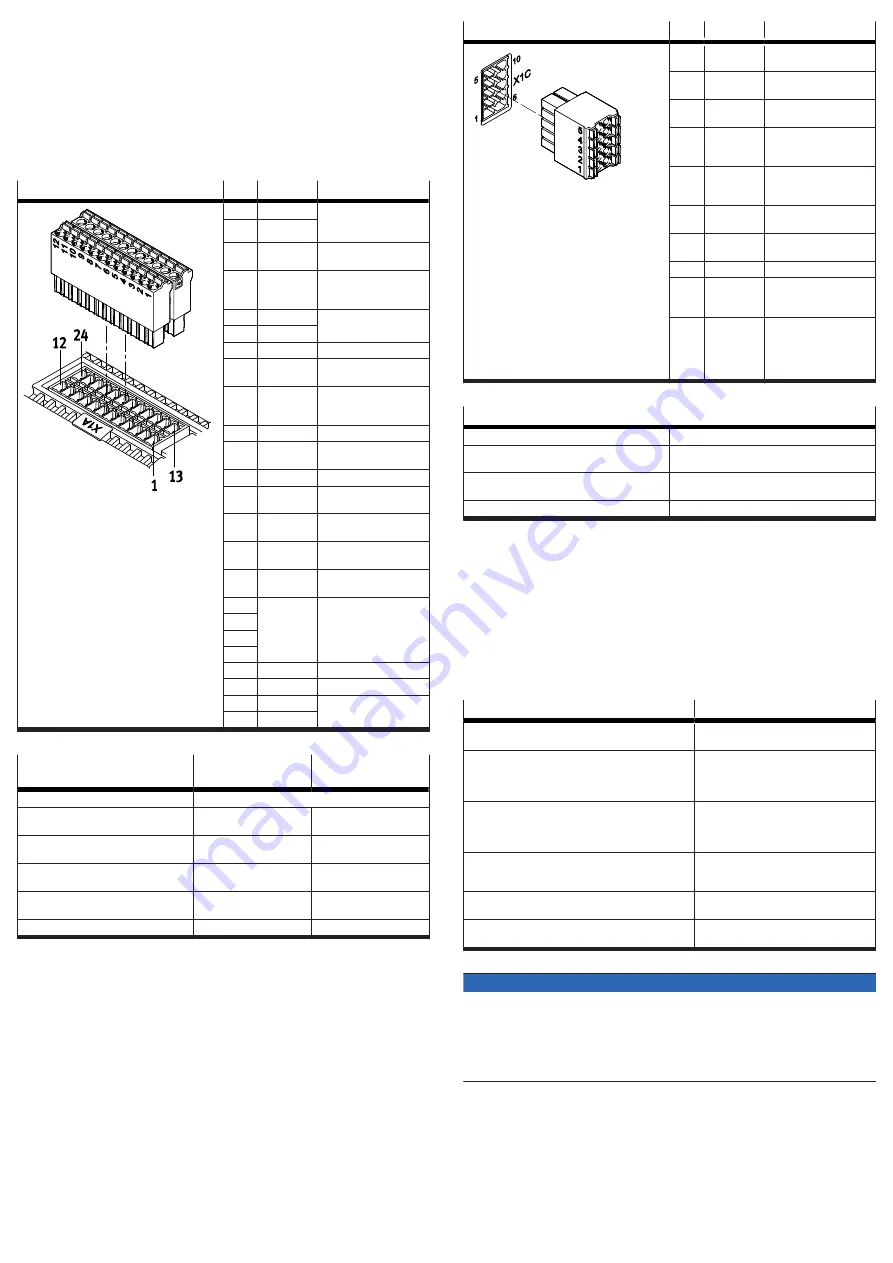

[X1A], inputs and outputs for the higher-order PLC

The I/O interface [X1A] is located on the top of the device. This interface offers

access to functional and safety-related inputs and outputs of the device. These

include, for example:

–

Digital inputs for 24 V level (PNP logic)

–

Digital outputs for 24 V level (PNP logic)

–

Signal contact for safety chain (RDY-C1, RDY-C2)

–

Differential analogue input ±10 V control voltage

The inputs and outputs of this I/O interface are used for coupling to a higher-

order PLC. The safety-related inputs and outputs are connected to a safety relay

unit.

[X1A]

Pin

Function

Description

24

RDY-C1

Normally open contact:

ready for operation mes-

sage (Ready)

23

RDY-C2

22

STA

Diagnostic output Safe

torque off acknowledge

21

SBA

Diagnostic output Safe

brake control acknowl-

edge

20

–

reserved, do not connect

19

–

18

SIN4

Release brake request

17

GND

Reference potential

(ground)

16

TRG0

fast output for triggering

external components,

channel 0

15

TRG1

like TRG0, but channel 1

14

CAP0

fast input for position

detection, channel 0

13

CAP1

like CAP0, but channel 1

12

#STO-A

Control input Safe torque

off, channel A

11

#STO-B

Control input Safe torque

off, channel B

10

#SBC-A

Control input Safe brake

control, channel A

9

#SBC-B

Control input Safe brake

control, channel B

8

–

reserved, do not connect

7

6

5

4

ERR-RST

Error acknowledgement

3

CTRL-EN

Power stage enable

2

AIN0

Differential analogue

input

1

#AIN0

Tab. 15: Inputs and outputs for the higher-order PLC with the CMMT-AS-...-S1

Requirements for the connecting

cable

Single device

Device compound

Shielding

Unshielded

Min. conductor cross section incl.

wire end sleeve with plastic sleeve

0.25 mm

2

–

Max. conductor cross section incl. plastic

wire end sleeve

0.75 mm

2

–

Min. conductor cross section incl. double

wire end sleeve with plastic sleeve

–

0.25 mm

2

Max. conductor cross section incl. double

wire end sleeve with plastic sleeve

–

0.5 mm

2

Max. length

3 m

0.5 m

Tab. 16: Requirements for the connecting cable

7.8.2

[X1C], inputs and outputs for the axis

The I/O interface [X1C] is located on the front of the device. This interface makes

functional and safety-related inputs and outputs available for components on the

axis. Output BR-EXT is used in conjunction with the safety sub-function Safe brake

control

è

Manual Safety sub-function.

[X1C]

Pin

Function

Description

10

GND

Reference potential

(ground)

9

24V

Power supply output for

sensors

8

GND

Reference potential

(ground)

7

LIM1

Digital input for limit

switch 1 (PNP logic,

24 V DC)

6

LIM0

Digital input for limit

switch 0 (PNP logic,

24 V DC)

5

GND

Reference potential

(ground)

4

24 V

Power supply output for

sensors

3

–

reserved, do not connect

2

REF-A

Digital input for refer-

ence switch (PNP logic,

24 V DC)

1

BR-EXT

Output for connection of

an external clamping unit

(high-side switch, low

test pulses at #SBC-B are

transferred to BR-EXT)

Tab. 17: Inputs and outputs for the axis

Cable requirements

Shielding

unshielded/shielded

1)

Min. conductor cross section including wire end

sleeve with plastic sleeve

0.25 mm

2

Max. conductor cross section including wire end

sleeve with plastic sleeve

0.75 mm

2

Max. length

100 m

1) Use a shielded cable outside the control cabinet for safety engineering applications. Otherwise, a shield is

not absolutely essential, but is recommended.

Tab. 18: Cable requirements

Shield support requirements

Connecting the shield

1. On the device side, connect the cable shield to the shield clamp for the motor

cable.

2. On the machine side, connect the cable shield to an earthed machine part.

7.8.3

[X2], encoder interface 1

The encoder interface [X2] is located on the front of the device. The encoder

interface [X2] is primarily designed for connecting the position encoder integrated

into the motor.

Supported standards/protocols

Supported encoders

Hiperface

SEK/SEL 37

SKS/SKM 36

EnDat 2.2

ECI 1118/EBI 1135

ECI 1119/EQI 1131

ECN 1113/EQN 1125

ECN 1123/EQN 1135

EnDat 2.1

Only in conjunction with Festo motors

from the series EMMS-AS that have an

integrated encoder with EnDat 2.1 pro-

tocol

Digital incremental encoders with square-wave signals

and with RS422-compatible signal output (differential

A, B, N signals)

ROD 426 or compatible

Analogue SIN/COS incremental encoders with differen-

tial analogue signals with 1 V

ss

HEIDENHAIN LS 187/LS 487 (20 µm signal

period) or compatible

Encoders with asynchronous two-wire communication

interface (RS485)

Nikon MAR-M50A or compatible (18 bit

data frames)

Tab. 19: Standards and protocols supported by the encoder interface [X2]

NOTICE

Damage to the sensor when sensor type is changed.

The servo drive can provide 5 V or 10 V sensor supply. Through configuration of

the sensor, the supply voltage is established for the sensor. The sensor can be

damaged if the configuration is not adjusted before connection of another sensor

type.

• When changing the sensor type: Comply with specified steps.

Change of encoder type

1. Disconnect encoder from the device.

2. Set up and configure new encoder type in the CMMT-AS.

3. Save settings in the CMMT-AS.

4. Switch off CMMT-AS.

5. Connect new encoder type.

6. Switch CMMT-AS back on.