Property

Value

Comments

Tightening torque for the

retaining screws in the case of

block mounting

1.8 Nm ± 15%

In the case of block mounting,

the shield clamp makes full

contact with the base of

the housing (cable diameter

12 mm)

Minimum tightening torque

with larger cable diameter

(

>

12 mm … 23 mm)

0.5 Nm ± 15%

With a higher tightening

torque, make sure that the

connecting cable does not get

crushed in the clamping area

due to excessive pressure.

Tab. 35: Tightening torque and clamping range CMMT-AS-...-C7/C12-11A-P3

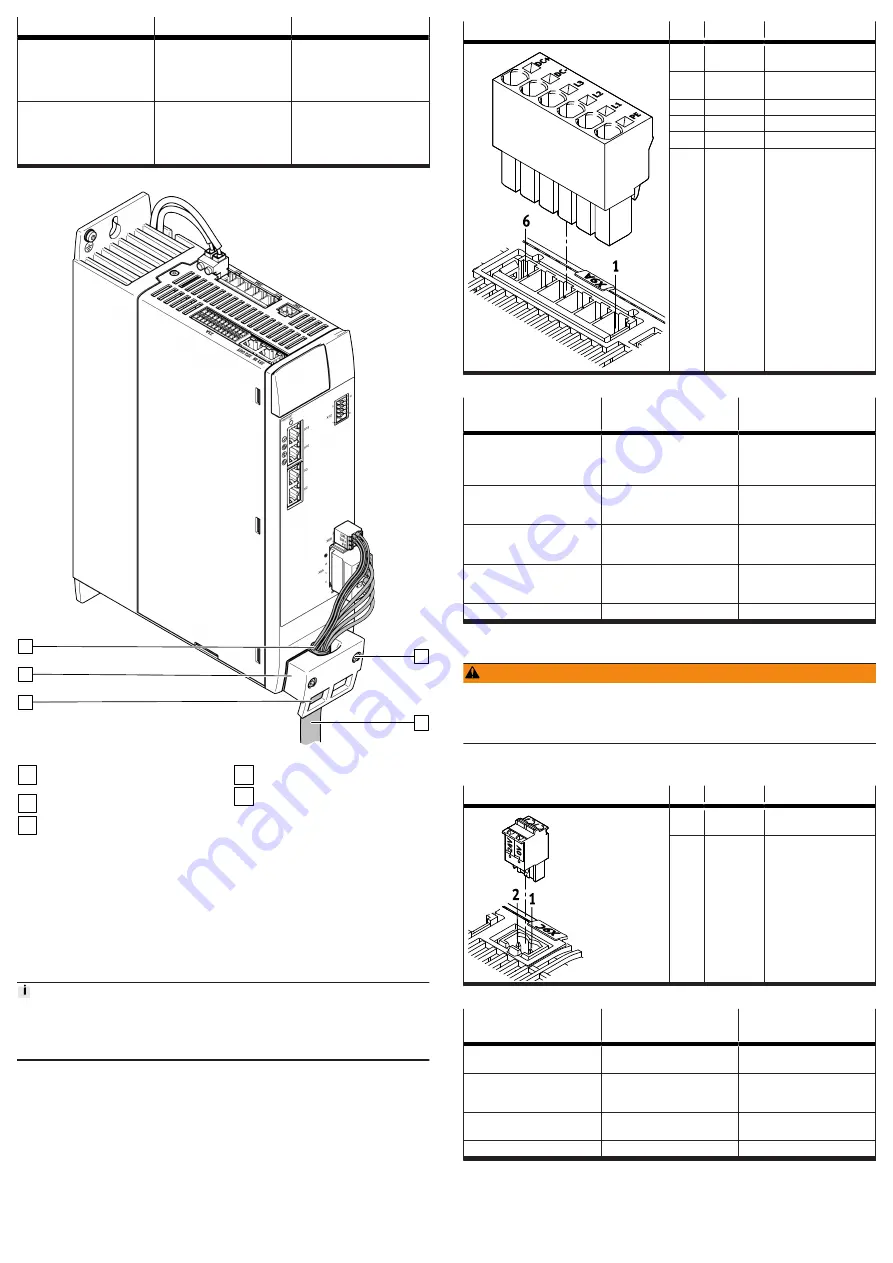

1

2

3

4

5

Fig. 10: Shield clamp of the motor cable

1

Retaining screws of the shield

clamp (2x)

2

Motor cable

3

Cut-out for mounting cable

binders (2x)

4

Shield clamp

5

Shield of the motor cable posi-

tioned under the shield clamp

over a wide area

Motor cable shield support on the motor side

Detailed information on the motor-side connection with motor cables from Festo

è

Assembly instructions for the motor cable

•

Connect all shields to the PE over a wide surface area on the motor side,

e.g. via the shield connection provided on the motor connector or the shield

support surface in the motor junction box.

7.10

Power and logic voltage supply

7.10.1

[X9A], power supply and DC link circuit connection

The connections for the power voltage supply and the DC link circuit are not

protected against wiring errors. The reversal of the connections results in a device

defect during switch-on.

With cross-wiring, observe the polarity of the DC link connection on all devices.

[X9A]

Pin

Function

Description

6

DC+

DC link circuit positive

potential

5

DC-

DC link circuit negative

potential

4

L3

Mains supply phase L3

3

L2

Mains supply phase L2

2

L1

Mains supply phase L1

1

PE

Protective earthing

Tab. 36: Power supply and DC link circuit

Requirements for the

connecting cable

Single device

Device compound

Number of insulated wires and

shielding

4 insulated wires, unshielded

Without DC link coupling:

4 wires, unshielded

With DC link coupling: 6 wires,

unshielded

Min. conductor cross section

including wire end sleeve with

plastic sleeve

0.5 mm

2

1.5 mm

2

Max. conductor cross section

including wire end sleeve with

plastic sleeve

4 mm

2

4 mm

2

Max. conductor cross section

including wire end sleeve

without plastic sleeve

6 mm

2

6 mm

2

Max. length

2 m

£

0.5 m

Tab. 37: Requirements for the connecting cable

7.10.2

[X9C], logic voltage supply

WARNING

Risk of injury due to electric shock.

• For the electrical power supply with extra-low voltages, use only PELV circuits

that guarantee a reinforced isolation from the mains network.

• Observe IEC 60204-1/EN 60204-1.

•

Only connect PELV circuits with an output current of max. 25 A. Otherwise,

use a separate external fuse: 25 A.

[X9C]

Pin

Function

Description

2

24 V DC

Positive potential of logic

voltage supply

1

0 V

Reference potential for

logic voltage supply

Tab. 38: Logic voltage supply

Requirements for the

connecting cable

Single device

Device compound

Number of insulated wires and

shielding

2 insulated wires, unshielded

2 insulated wires, unshielded

Min. conductor cross section

incl. wire end sleeve with

plastic sleeve

0.5 mm

2

0.5 mm

2

Max. conductor cross section

incl. plastic wire end sleeve

2.5 mm

2

2.5 mm

2

Max. length

2 m

0.5 m

Tab. 39: Requirements for the connecting cable

7.10.3

[X9B], connection for braking resistor

The connection [X9B] is located on the top of the device. The internal braking

resistor or a suitable external braking resistor is attached to the connection [X9B].