Rendimax N EL

21

Note if after having correctly performed the ignition operation, the burners do not light and the reset button light

on the electronic control unit is on, indicating that the control unit is blocked, wait around 10 seconds and then

press the reset button.

The control unit is reset and will repeat the ignition cycle.

If, after the second attempt, the burners do not light, refer to paragraph 13 “troubleshooting”.

In the event of power failures, the burners will shut-down and will be automatically ignited once the power retur-

ns.

10.04 Temporary shut-down

To temporarily shut-down the boiler, simply place the boiler switch in position “0”.

10.05 Extended boiler shut-down

To shut the boiler down, proceed as follows:

• Turn the knob of the boiler switch to position ”0”;

• Close the gas cock upstream from the boiler;

• Disconnect power to the appliance.

N.B.

If the boiler is not used for an extended period in winter, to avoid damage from frost, special anti-freeze

should be added to the system, or else the system should be completely emptied.

10.06 checks after ignition

Following the first ignition:

• Check the gas circuit and the heating system for tightness.

• Check the correct operation of the boiler by effecting ignition and shut-down tests using the regulation

thermostat.

• Check on the rear wall of the boiler, at the height of the draught diverter, that there are no flue gas leaks, signs

of blockages of the flue or insufficient draught.

• Check the effectiveness of the flue during boiler operation.

• Check that the connecting pipe between the boiler and flue is perfectly sealed at the joints.

• Verify that the circulation of water between the boiler and the heating system is correct.

• Make sure that, in the absence of a flame in the burner assembly, the appliance shuts-down.

11. SETTINGS

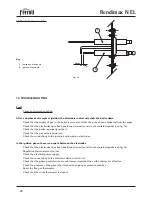

11.01 setting the heating temperature

The central heating water temperature is set by turning the knob on the boiler thermostat, on the control panel.

Turn the knob clockwise to increase the central heating water temperature; anticlockwise to decrease it. The mi-

nimum temperature setting must not be below 50°.

11.02 setting the ambient temperature (with room thermostat installed)

The ambient temperature is set by turning the knob on the room thermostat to the desired value. This device,

which is not supplied with the boiler, maintains the ambient temperature at the value set on the knob, reducing

energy consumption and increasing the level of comfort.

Содержание RENDIMAX N EL

Страница 2: ......

Страница 28: ...FERROLI S p A Via Ritonda 78 a 37047 San Bonifacio Verona ITALY www ferroli it...