Rendimax N EL

20

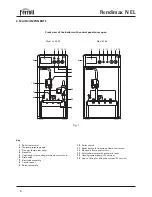

9.02 opening the control panel

To access the electrical components inside the control panel, follow the sequence in fig. 10.

fig. 10

10. SET-UP

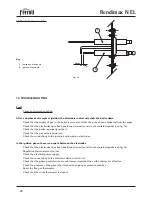

10.01 fi rst ignition

The first ignition and the training of the user for the correct operation of the boiler must be carried out by an

authorised service centre.

10.02 checks to be performed upon fi rst ignition

During the first ignition of the boiler, it is important to check that the on-off valves between the boiler and the

heating system are open; that the heating circuit is filled and vented of air; that there are no gas or water leaks in

the heating system or in the boiler; that the electrical connections are correct and that the earth cable is connected

to an adequate earth system; that there are no inflammable liquids or materials in the immediate vicinity of the

boiler; and that the flue is not blocked.

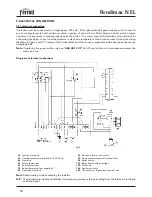

10.03 ignition

Set the boiler thermostat to the “minimum temperature” position, and power the appliance using the boiler

switch.

To ignite the burner assembly, proceed as follows:

• Open the gas cock (fitted by the installer);

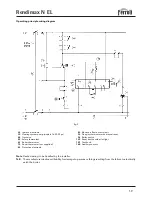

• Vent the air in the gas pipes using the air vent fitted upstream from the gas valve (fig. 11).

• Adjust the knob on the boiler thermostat to the desired value (not less than 50 °C.).

At this stage the electronic control unit starts operating and will pilot, after a set waiting time, the gas valve and

the spark to the ignition electrode, which in turn will light the burner assembly. The ionisation electrode then checks

the presence of the flame in the burner assembly.

The boiler operates automatically, controlled by the boiler thermostat and/or any other control devices (room

thermostat, electronic temperature control unit, etc.).

3

1

5

2

4

Key

1

Boiler cover

2

Protective cover fastening screw

3

Wiring protective cover

4

Fastening plate and screw

5

Control panel

Содержание RENDIMAX N EL

Страница 2: ......

Страница 28: ...FERROLI S p A Via Ritonda 78 a 37047 San Bonifacio Verona ITALY www ferroli it...