OPTIMAX HE 31 S

25

Cod. 3540F441 - 03/2007 (Rev. 01)

3.2 System start-up

Commissioning must be performed by Qualified Personnel.

Checks to be made at first ignition, and after all maintenance operations that involved discon-

necting from the systems or an intervention of a safety device.

Before lighting the boiler:

• Open any isolation valves between the boiler and the system.

• Check the tightness of the gas system, proceeding with caution and use gas leak detection fluid to

detect any leaks in connections.

• Check the pre-filling of the expansion tank (ref. sec.4.4)

• Fill the water system and make sure that all air contained in the boiler and the system has been vented

by opening the air vent valve on the boiler and any vent valves on the system.

• Make sure there are no water leaks in the system, hot water circuits, connections or boiler.

• Make sure the electrical system is properly connected.

• Make sure that the unit is connected to a good earthing system.

• Make sure there are no flammable liquids or materials in the immediate vicinity of the boiler.

• Vent and spin the pump.

• Ensure the flue system is correctly fitted, including terminal locations.

Ignition

• Open the gas valve upstream of the boiler.

• Purge the air from the installation pipework to the appliance.

• Switch on the boiler electrical supply.

• Press the

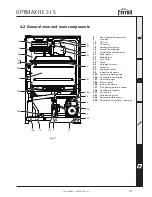

key on the boiler for 5 seconds (part. 7 - fig. 1).

• The boiler is now ready to function automatically whenever the external controls call for a demand.

In case of an electrical power failure while the boiler is working, the burner will go out. When

power returns, the boiler will run the self-test cycle again, after which the burner will automatically

re-ignite (if there is still demand for heat).

Checks during operation

• Check the tightness of the gas circuit and water systems.

• Check the efficiency of the flue and air-flue ducts while the boiler is working.

• Check that the water is circulating properly between the boiler and the system.

• Make sure that the gas valve modulates correctly.

• Check the proper ignition of the boiler by performing various tests, turning it on and off with the

room thermostat or remote control.

• Make sure that the fuel consumption indicated on the meter corresponds to that given in the technical

data table in section 4.4 page 33

Turning off

Press the

key for 5 seconds (part. 7 - fig. 1).

Содержание OPTIMAX HE 31 S

Страница 36: ......