5

1 . FEBCO backflow prevention assemblies can be serviced with standard

tools and are designed for ease of maintenance . The assemblies are

designed to be serviced in line, so the unit should not need to be

removed from the line during servicing . NO special tools are required .

2 . The most common cause of check fouling is dirt and debris in the

seating areas . The line should be flushed clean of debris before instal-

lation of the assembly . To flush the line after installation of the assem-

bly, slowly close the inlet shutoff valve, remove the covers and spring

assemblies of both check valves and open the inlet shutoff valve to

allow sufficient flow of water through the assembly to clear all sand,

debris, etc . from the line . If debris in the water continues to cause

fouling, a strainer may be installed upstream of the assembly (check

local codes) .

3 . Rinse all parts with clean water before reassembly .

4 . Lubricant is recommended only for #2 check cover O-ring to help hold

O-ring in place during reassembly (Series 870V and 876V) . Apply a thin

coating of the lubricant supplied in the repair kit to the O-ring groove in

the #2 check body, and position the O-ring in the groove .

5 . Carefully inspect seals and seating surfaces for damage or debris . If

the check valve seat disc has been severely cut at the seat ring diam-

eter, the assembly has been subjected to extremely high and repeated

back pressure . Either thermal water expansion or water hammer are

the most likely causes . If back pressure persists, consider installation

of a pressure relief valve downstream of the assembly .

6 . Use caution to avoid damaging any guiding surfaces while handling

parts . Do not force parts together . The O-ring seals used in FEBCO

assemblies require only a small tightening force to insure a

positive seal .

7 . Test unit after servicing in accordance with locally approved test

methods to insure proper operation (See Page 5 for more details) .

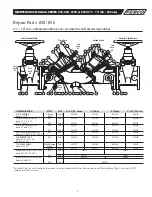

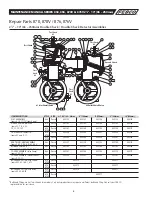

8 . Refer to applicable parts lists and cut-a-ways (Pages 11-13)

for visual aid information .

MAINTENANCE MANUAL SERIES 850, 856, 870V & 876V 2

1

⁄

2

"- 10" (65 – 250mm)

General Service Procedures

1

⁄

2

" - 10" (15-250mm)