56

Dispenser function test

1. After installing a new roller, the function, centering and smooth running must be checked.

2. To start the roller, use the metering fill function or the sowing test.

3.

The drive motor must run evenly “smoothly”.

4. Check clutch centering. If running unevenly, the dosing is inaccurate and the motor can be overloaded.

5. At the point where the roller cuts, repair them, they must be reground or returned.

6. Loosen the screws on the side covers for the drive motor and roller bearing, and realign the side covers

to prevent stress.

7. If the drive shaft is bent, it must be aligned or replaced.

8. If foreign bodies are stuck between the roller and the metering housing, they must be removed.

9. If there is dust or mordant in the roller between the metering discs and the spacer roller, disassemble and

clean the roller.

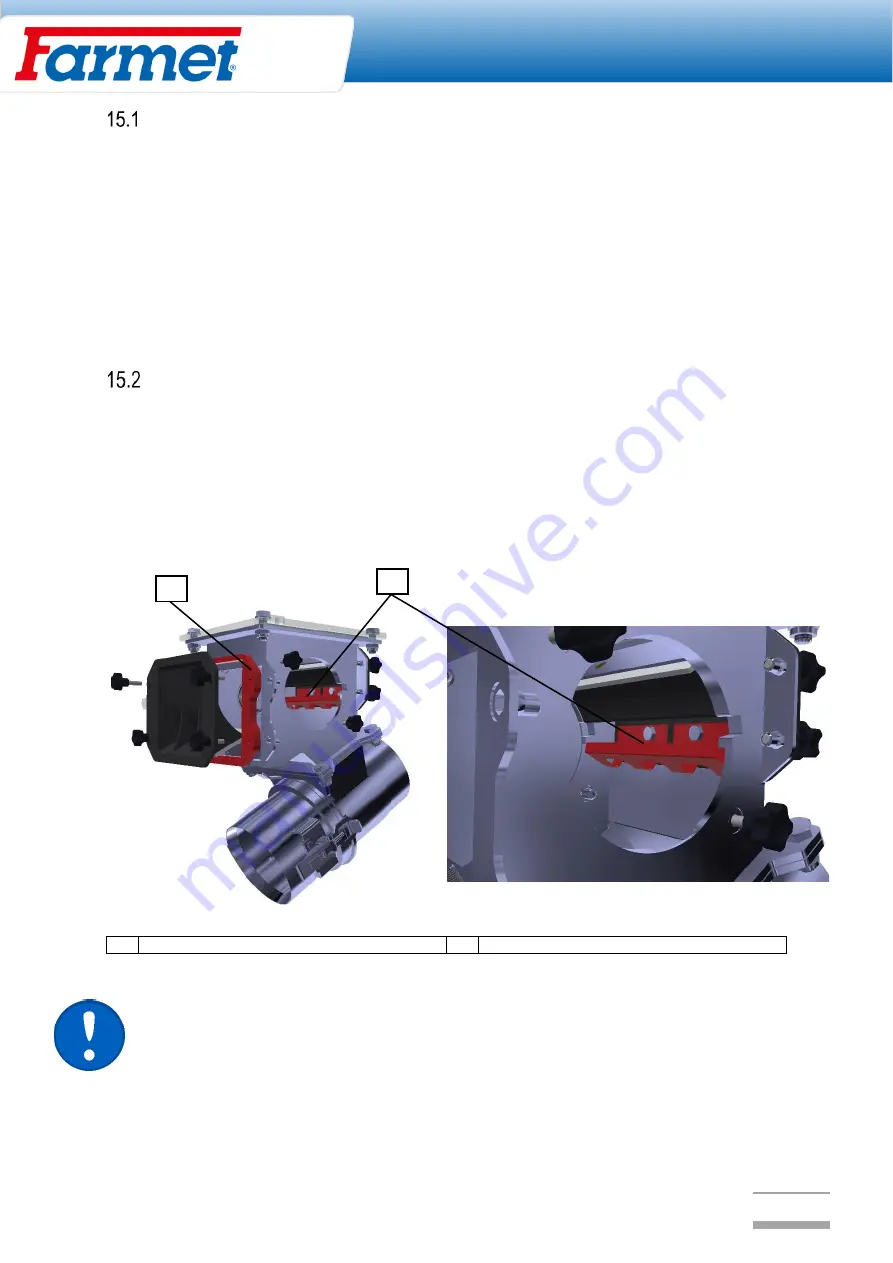

Rough seeds

-

For sowing rough seeds (corn, beans. peas, etc.) it is necessary to adjust the metering unit.

-

The deflector (1) prevents large seeds from getting stuck between the metering cover and the roller. Failure

to install the deflector could damage the roller, metering unit, or motor.

-

For very large grains, a large seed adapter (2) can be fitted. This makes it easier for large grains to enter

the dispenser and prevents grain damage.

-

If necessary, add talc or graphite powder to the seed. Some types of large seeds do not spread well and

may not completely fill the roller holes.

-

When using the adapter for large seeds, it is necessary to use longer fixing screws L= 30mm (accessories

of the adapter frame).

-

Deflector set with an adapter for large seeds is part of the machine accessories.

1

Deflector for large seeds

2

Adapter for large seeds

1

1

2

Содержание FALCON PRO

Страница 3: ...2 AGRICULTURAL MACHINES OIL FEED TECH...