©

FAR GROUP EUROPE

USING THE MILLING DRILLING HEAD

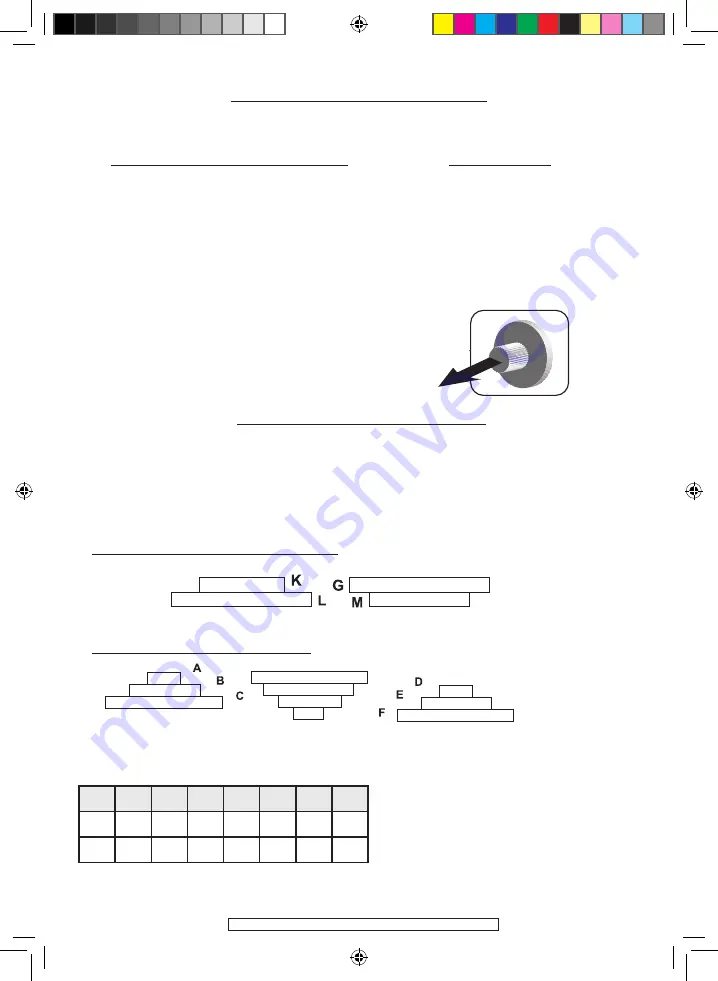

SETTING MILLING SPINDLE SPEEDS

DRILLING-MILLING HEAD PULLEYS

PULLEYS IN THE REAR CASING

When using the drilling/milling head and for improved ease of working, it is preferable

to remove the mandrel from the lathe.

There are 14 speed adjustment possibilities ranging from 117 to 1300 rpm. The spindle

speed is set depending on the diameter of the cutter or drill used and the material to

be machined or drilled. This is set after calculating the rpm and the position of the belts

on the pulleys..

RAISING / LOWERING THE HEAD

HEAD CLUTCH

Slacken the 6 mm hollow head

bolt using an 8 mm Allen wrench.

Turn the chromed ring using the

levers

- Clockwise to lower,

- Counter clockwise to raise, As

the head position is set, align

the drilling chuck axis with the

lathe spindle axis (to better use

the drilling head), Lock the head

using the hex head bolt.

To engage the drilling/milling

head:

Open the transmission system

door then push the knobbed

ring all the way in, which auto-

matically releases the lathe spin-

dle and engages the milling head

spindle

To change the drilling head belt posi-

tion:

Remove the casing,

Slacken the belt tensioner,

Change the position of the belts then

retighten the tensioner while applying

pressure to the belt.

Refit the casing.

A-F

A-E

A-D

B-F

C-F

B-E

C-D

K-G

150

290

360

450

575

836

1300

L-M

117

220

276

345

440

640

1000

Speed in rpm

Spindle pulleys

MOTOR PULLEYS

INTERMEDIATE PULLEYS

SPINDLE PULLEYS

114135-Manual-D-EN.indd 12

21/03/12 10:44:54

Содержание TDM 400B

Страница 5: ...FAR GROUP EUROPE SLAVED SAFETY CASING 114135 Manual D EN indd 5 21 03 12 10 44 23...

Страница 11: ...FAR GROUP EUROPE MOVING AND ADJUSTING THE TAILSTOCK CENTRE 114135 Manual D EN indd 11 21 03 12 10 44 53...

Страница 13: ...FAR GROUP EUROPE 114135 Manual D EN indd 13 21 03 12 10 44 55...

Страница 29: ...FAR GROUP EUROPE FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 29 21 03 12 10 45 06...

Страница 30: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 30 21 03 12 10 45 06...

Страница 31: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 31 21 03 12 10 45 06...

Страница 32: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 32 21 03 12 10 45 07...

Страница 33: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 33 21 03 12 10 45 07...

Страница 34: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 34 21 03 12 10 45 07...

Страница 35: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 35 21 03 12 10 45 08...

Страница 36: ...FAR GROUP EUROPE TDM 400B 114135 Manual D EN indd 36 21 03 12 10 45 08...