42

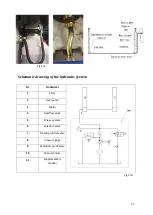

Adjusting the safety lock mechanism

CAUTION! Check the lift’s safety lock mechanism before each use for proper functioning, failure to

heed these instructions may cause serious damage to materials or serious injuries!

-

If the lock plate does not lean forward enough when it is unpowered, it will not be able to

block the lifting body, which allows the lift to keep lowering. You can adjust this by turning

the adjusting nut (5) on the back of the safety lock. Make sure the adjusting nut is secured

firmly after each adjustment!

-

If the lock plate does not retract far enough when powered, it will remain blocking the lifting

body, which will cause the lift not to lower. You can adjust this by turning the adjusting nut

(5) on the back of the safety lock. Make sure the adjusting nut is secured firmly after each

adjustment!

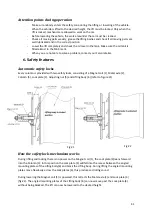

Foot safety height safety mechanism

When the bridge lowers, it stops at 30cm height, this is the foot safety height. To lower the lift, you

have to push the LOCK-button. This safety measure prevents people from getting their feet stuck

under the vehicle or arms of the lift. During this last phase of lowering a loud beep tone will sound to

alert people that the lift is lowering to its lowest position.

7.

Maintenance

Cleaning the lift

The lift regularly has to be cleaned using a wet cloth to keep it clean. Before cleaning set the main

power switch to 0-position, so the lift is not powered. The work area around the lift has to be swiped

clean. When large piles of dirt are gathered, this will accelerate the aging-proces of the lift, which

decreases the bridge’s lifetime.

General checks

-

Check all safety devices of the lift at the beginning of every day of work. The safety locks

have to fucnction properly, the lock plate always has to fall into position. The lifting body

may not show any signs of wear and tear, cracks and/or deformation. If a defect is

discovered, put the lift out of use immediately until the broken part or malfunction is

repaired by a professional mechanic.

-

Check the chains for backlash daily, this could cause the chains to hit the cylinder which

may damage the cylinders, also check if they are still properly mounted to the columns.

-

Daily check the steel cables, check if they are properly mounted/secured and if they are

properly tensioned.