8

bar

0

20

40

60

80

100

120

0

1

4

2

3

317

=

=

3

2

1

4

5

98

56

56

98

25

100

800

440

=

=

156

60

111

36

111

5

6

4

3

2

1

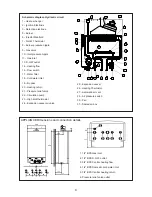

1. 1/2” BPS Gas inlet

2. 1/2” BPS D.H.W. outlet

3. 3/4” BPS Central heating flow

4. 1/2” BPS Domestic cold water inlet

5. 3/4” BPS Central heating return

6. Pressure relief valve outlet

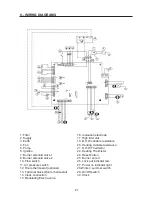

Schematic diagram- Hydraulic circuit

1.- Heat exchanger

2.- Ignition

Electrode

3.-

Detection electrode

5.- Burner

6.- Injector Manifold

7.- D.H.W Thermistor

8.-

Burner

pressure nipple

9.- Gas valve

10.- Inlet pressure nipple

11.- Gas inlet

13. D.H.W outlet

14.- Heating flow

16.- Flow switch

17.- Water filter

18.- Cold water inlet

19.- By-pass

20.- Heating return

21.- Pressure relief valve

22.- Circulation pump

23.-

High limit

thermostat

24.- Expansion vessel

air valve

25.- Expansion vessel

26.- Heating Thermistor

27.- Automatic air vent

29.- Air pressure switch

30.- Fan

31.-

S

ealed

air box

27

1

2

3

5

6

7

8

9

10

11

13

14

16

17

18

19

20

21

22

23

24

25

26

29

30

31

APPLIANCE Dimensions and connection details

Содержание FEB-20E UK ECOPLUS

Страница 1: ...FEB 20E UK ECOPLUS USER INSTRUCTIONS AND TECHNICAL INSTRUCTIONS...

Страница 23: ......