4

1.5.- HOT WATER AND CENTRAL

HEATING SERVICE

Turn the main control switch to the winter setting.

The burner will automatically fire up. By means of the central heat-

ing temperature selector control knob,any water temperature of

between 60 and 85°C may be selected. The boiler will remain on

until the temperature selected on the room thermostat or on the

boiler itself is reached.

Whenever there is a demand for D.H.W. from the central heating

setting, the boiler is ready to supply it giving priority to the D.H.W,

with the central heating on standby until the D.H.W. demand cease

GENERAL GUIDANCE NOTES ON HOT WATER DELIVERY

This boiler has a temperature modulation system to control the hot water delivery temperature. However

there are certain circumstances which can “cheat” the system causing a wide variation of temperature at the

outlet. These notes are designed to help the user obtain the best possible performance from the boiler and

avoid situations which could result in unsatisfactory performance.

-

The boiler can theoretically supply more than one outlet simultaneously However in practice the tap which

is nearest will receive the most hot water. If the shower is in use and a kitchen tap is opened virtually all

the hot water will be diverted to the kitchen as it offers the least resistance.

-

If an outlet is too restrictive it will slow down the flow rate and increase the temperature. For example the

shower - ensure the head is free from blockages caused by scale.

-

Due to the restrictive nature of simple mixer showers it is wise to turn the temperature selector down on

the boiler before using the shower.

-

If a tap or shower head is too restrictive due to a fault or blockage, the flow rate will be reduced to below

the rate at which the boiler is able to modulate resulting in a wide swing in temperatures. Either fix the

restriction or turn the temperature selector on the boiler down.

-

Caution: The boiler can produce water at over 80

°°

C when in central heating mode. If you run a hot

tap when the boiler has been heating the radiators, the initial flow through the hot tap could be

very hot. DO NOT PLACE YOUR HANDS under the tap or use the shower until this initial flow has

passed.

-

Allow time (30 seconds) for the temperature to stabilise after making an adjustment at the tap before mak-

ing further adjustments.

TURNING THE BOILER OFF

Turn the main control switch to the O setting.

Turn off the gas supply to the boiler

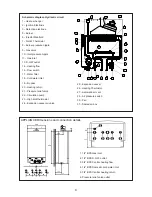

USING THE PROGRAMMABLE TIMER

1. To set correct time rotate minute hand until arrowhead aligns with correct time.

2. To set on/off times move all tappets between ‘on’ and ‘off’ times

required to outer position. is to set ‘on’ at 8am and off at 11am

move all tappets between 8 and 11 to outer position.

3. Set as many on/off times as required within a 24 hour period in

a similar manner to step 2.

4. Manual override switch: This has 3 positions.

-

In position I (uppermost) the timeswitch is permanently ‘on’

regardless of tappet positions.

-

In the middle position the timeswitch is operating on timed control and will only switch ‘on’ and ‘off’ as

determined by tappet positions.

-

In position O (lowest) the timeswitch is permanently off irrespective of tappet positions

3

2

1

4

6

3

9

12

1

Position: min. max

Содержание FEB-20E UK ECOPLUS

Страница 1: ...FEB 20E UK ECOPLUS USER INSTRUCTIONS AND TECHNICAL INSTRUCTIONS...

Страница 23: ......