·226·

Operating manual

CNC 8055

CNC 8055i

13.

DIAGNOSIS

·T· M

ODEL

S

OFT

: V02.2

X

Adjustments

13.4

Adjustments

13.4.1

Circle geometry test

This adjustment improves the axis reversal peaks. It consists in machining a circle (without

compensation) and verifying it on the graph displayed at the CNC.

The following example shows a program that machines repetitive circles.

X0 Y0

G5 G1 F1000

N10 G2 X0 Y0 I20 J0

(RPT N10, N10) N50

M30

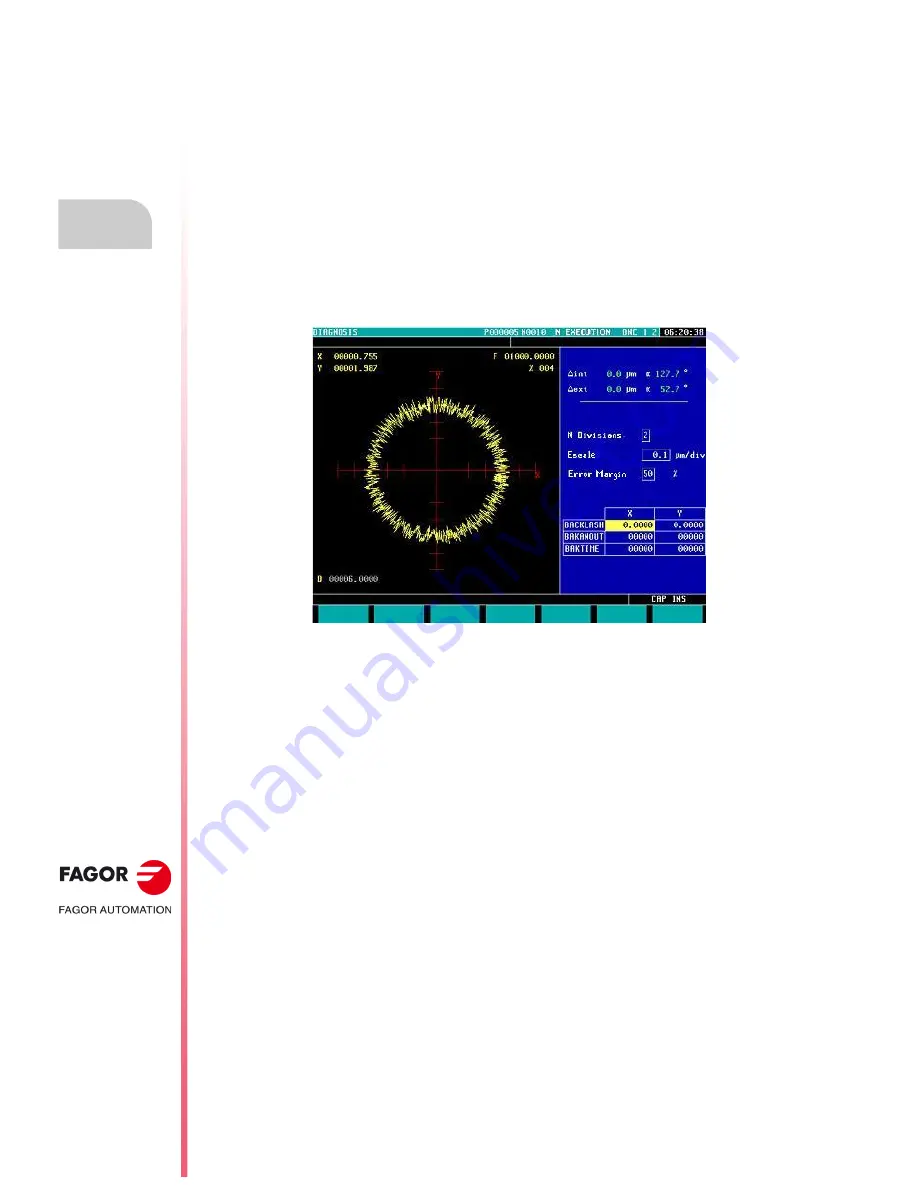

After selecting this program in the Execution mode and starting it, access the "Diagnosis,

Adjustments, Circle Geometry test" mode and the CNC will display the following screen:

If the machine parameters are protected, it will request the access password because the bottom

right of the screen shows some of them. When not knowing the password, those values cannot be

changed, but it will be possible to access the screen and the circle geometry test.

The left side of the CNC screen shows the result of the test.

The data at the top right is refreshed by the CNC after the test is completed.

The data at the center right must be defined before running the test.

The bottom right side of the screen shows the parameters associated with the plane axes and the

values to set them.

The graph on the left must be defined before running the test. To do that, define the data of the center

right:

• Number of divisions to the left and to the right of the theoretical circle.

• Scale or value in microns of each division.

• Error margin or % of circle radius occupied by the error margin (divisions area).

Knowing the password, the values shown at the bottom right may be modified. The CNC assigns

the new values to the relevant machine parameters; therefore, it is recommended to jot the initial

values down.

Содержание CNC 8055

Страница 1: ...CNC 8055 T Operating manual Ref 1705 Soft V02 2x...

Страница 6: ...6 Operating manual CNC 8055 CNC 8055i T MODEL SOFT V02 2X...

Страница 10: ...18 CNC 8055 CNC 8055i Declaration of conformity and Warranty conditions...

Страница 14: ...10 CNC 8055 CNC 8055i Version history...

Страница 20: ...16 CNC 8055 CNC 8055i Returning conditions...

Страница 22: ...20 CNC 8055 CNC 8055i Additional notes...

Страница 24: ...22 CNC 8055 CNC 8055i Fagor documentation...

Страница 38: ...38 Operating manual CNC 8055 CNC 8055i 1 OVERVIEW T MODEL SOFT V02 2X Layout of the operator panel...

Страница 46: ...46 Operating manual CNC 8055 CNC 8055i 2 OPERATING MODES T MODEL SOFT V02 2X KeyCF KeyCompactFlash...

Страница 124: ...124 Operating manual CNC 8055 CNC 8055i 6 MANUAL T MODEL SOFT V02 2X Spindle movement...

Страница 134: ...134 Operating manual CNC 8055 CNC 8055i 7 TABLES T MODEL SOFT V02 2X Tool Offset table...

Страница 135: ...Operating manual CNC 8055 CNC 8055i TABLES 7 T MODEL SOFT V02 2X 135 Tool Offset table...

Страница 138: ...138 Operating manual CNC 8055 CNC 8055i 7 TABLES T MODEL SOFT V02 2X Tool geometry table...

Страница 196: ...196 Operating manual CNC 8055 CNC 8055i 10 PLC T MODEL SOFT V02 2X Logic analyzer...

Страница 212: ...212 Operating manual CNC 8055 CNC 8055i 11 GRAPHIC EDITOR T MODEL SOFT V02 2X Modifications...

Страница 220: ...220 Operating manual CNC 8055 CNC 8055i 12 MACHINE PARAMETERS T MODEL SOFT V02 2X Operation with parameter tables...

Страница 240: ...240 Operating manual CNC 8055 CNC 8055i 13 DIAGNOSIS T MODEL SOFT V02 2X Interesting notes...

Страница 252: ...252 Operating manual CNC 8055 CNC 8055i 14 CNC PC COMMUNICATION TELEDIAGNOSIS T MODEL SOFT V02 2X Internet phone call...

Страница 253: ...Operating manual CNC 8055 CNC 8055i 14 T MODEL SOFT V02 2X 253...

Страница 254: ...254 Operating manual CNC 8055 CNC 8055i 14 T MODEL SOFT V02 2X...

Страница 255: ......