E

XAMPLE

MANUAL

53

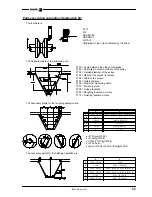

a=P107/cos(P100/2)

b=P106

∗

tg(P100/2)

c=(P103-P107)

∗

tg(P100/2)

d=P104-2a-2c

e=[(x/2)-((P102/2)-P103+P107)]

∗

tg(P100/2)

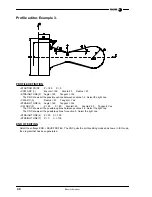

Pulley executing subroutine (Subroutine 50)

The tool data is:

D=12

F=2

NOSEA=90

NOSEW=4

CUTA=0

Calibrated for the corner indicated by the arrow.

The Call parameters of the subroutine are:

P100 = Angle between the sides of the pulley.

P101 = Absolute Z center coordinate of the pulley.

P102 = Outside diameter of the pulley.

P103 = Depth of the groove (in radius).

P104 = Width of the groove.

P105 = Safety distance.

P106 = Maximum machining depth.

P107 = Finishing stock.

P108 = Cutting feedrate.

P109 = Roughing feedrate in mm/rev.

P110 = Finishing feedrate mm/rev.

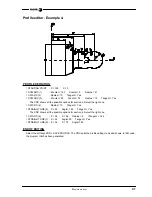

The necessary points for the roughing operation are:

The necessary points for the finishing operation are:

X

Z

1

P102 + 2 P105

P101

2

P102

P101 + (P104 /2)

3

P102 - 2P103

P101 + (P104 /2) - P103 tg (P100 /2)

4

P102 - 2P103

P101 - (P104 /2) + P103 tg (P100 /2)

5

P102

P101 - (P104 /2)

6

P102 + 2 P105

P101 - (P104 /2)

X

Z

A

P102 + 2 P105

P101 + (P104 /2) - [P107 /cos (P100/2)]

A-B

- 2 P105

0

B-C

- 2 P106

- P106 tg (P100 /2)

C-D

0

- (d + 2e)

D-E

- 2 P106

P106 tg (P100 /2)

E-F

0

d + 2e

Содержание CNC 8055 T

Страница 1: ...REF 1010 8055 T Examples manual CNC...

Страница 4: ...EXAMPLE MANUAL 1 TOOLS List of tools used in these examples...

Страница 7: ...4 EXAMPLE MANUAL User Notes...

Страница 35: ...32 EXAMPLE MANUAL User Notes...

Страница 39: ...36 EXAMPLE MANUAL User Notes...

Страница 45: ...42 EXAMPLE MANUAL User Notes...

Страница 46: ...43 Programming examples User screen customizing programs 8055T Machine diagnosis 44 Machining a pulley 52...