Ø 10,5 mm

=

=

ENGLISH

4

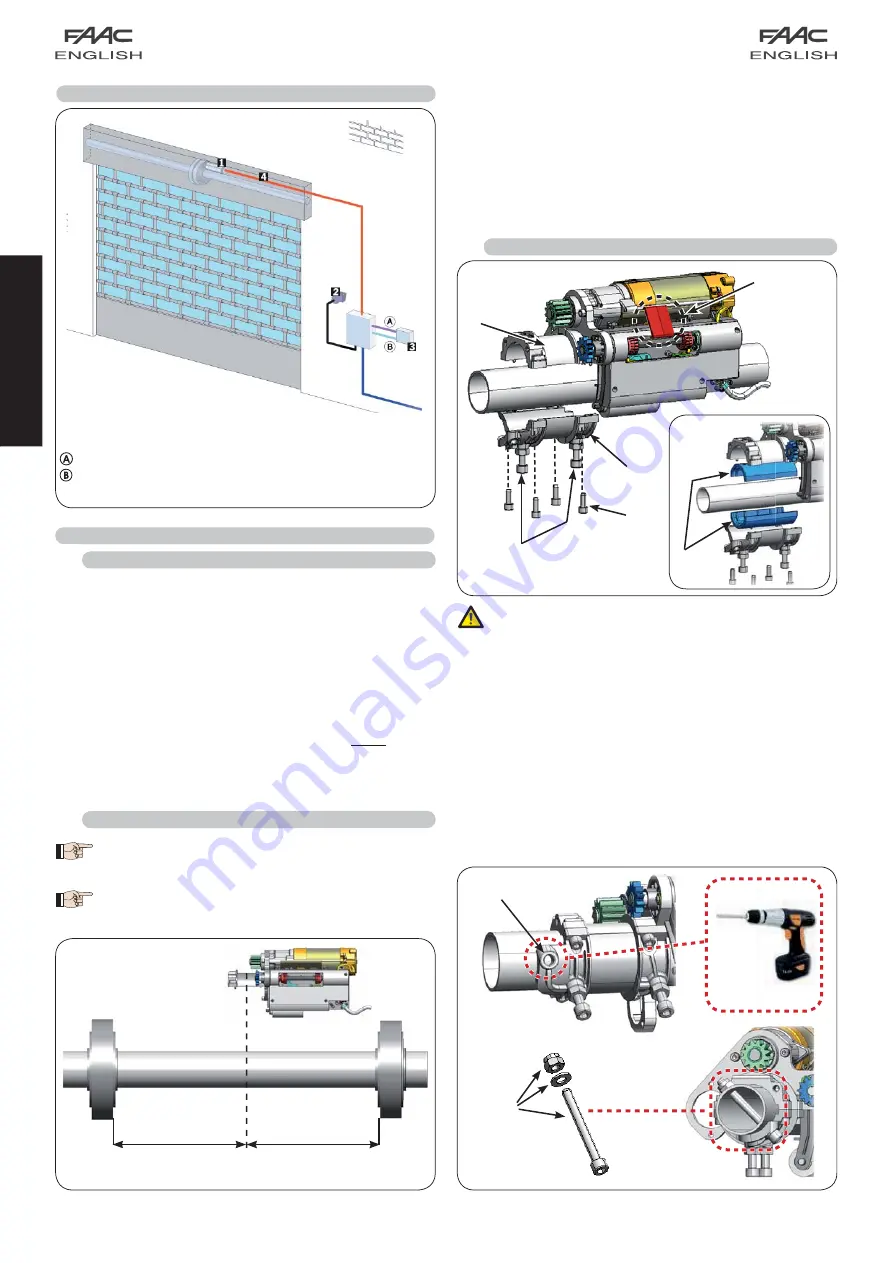

3 INSTALLING THE AUTOMATED SYSTEM

2 ELECTRIC

PREPARATIONS

(standard system)

3.1 PRELIMINARY

CHECKS

To ensure a correctly operating automated system, the structure

of the existing shutter or shutter to be built must satisfy the following

requirements:

• Dimensions and maximum weight as per specifications in Tab. 1.

• Strong, well constructed shutter structure.

• Smooth rise and descent movement, free of any irregular friction along

its entire travel.

• The rotation pins and moving parts must be in good condition.

• Shutter well balanced during its entire travel.

We advise you to carry out the metalwork jobs if any, before installing

the application.

The condition of the structure directly influences the reliability and safety

of the automated system.

3.2 INSTALLATION

DIMENSIONS

3.3 INSTALLING THE OPERATOR

Drive unit FAAC R180 / R280

Key operated switch

Electronic control board

Optional electro-brake

Low voltage cable No.1= 3 x 0,5 mm

High voltage cables No.1 2 x 1,5 mm

2

+ earth

and No. 1 3 x 1,5 mm

2

+ earth

Fig. 4

Fig. 6

Fig. 5

Before taking the necessary measurements, accura-

tely clean the shutter shaft removing deposits of dust,

grease and chips, …

To install two R180 or R280 operators on a shutter

having a width of over 4.5 meters, please refer to

chapter 8 on page 8.

Procedure for defining the correct position of the operator:

Fully unwind the shutter to obtain access to the winding shaft;

As shown in Fig. 5, find the mid-point of the winding shaft and mark

it for subsequent use;

Install the operator, following the instructions in chapter 3.3,

positioning the electric motor on the right of the shaft as shown in

Fig. 5.

1.

2.

3.

During the installation operations, take great care NOT TO

REMOVE the service bracket, ref.

Fig.6, in order not to

compromise the initial position of the travel-limit devices.

Install the operator as follows:

Position the operator body on the shaft, with the central part of

the securing flange (ref.

of Fig.6) on the mid-point previously

measured in chapter 3.2;

If winding shafts with a diameter of 48 or 42 mm (previously

measured in chapter 1.2) are being used, fit the supplied reductions

as shown in Fig. 6A ref.

;

Close the securing flange with its counterpart in ref.b, using the four

screws in ref.

;

Tighten CAREFULLY the operator on the winding shaft, using the

two pressure screws and relevant lock-nuts in ref.

, reducing the

cupling spaces;

1.

2.

3.

4.

Fig. 7

Fig. 6A