71

70

EN

EN

V. Work with the nail/

staple gun

1. Place the nail/staple gun with the contact switch

against the surface of the workpiece (fig. 5a, step 1).

2. Push the nail/staple gun against the surface of the

workpiece without pressing the trigger, so that the

contact switch is compressed (fig. 5b, step 2).

•

ATTENTION

y

The nail/staple gun is not intended for driving nails/

staples into hard surfaces such as steel or concrete!

When driving nails/staples into materials on a steel,

concrete, etc. base, it is necessary to apply a greater

downward force due the greater recoil and to pre-

vent the gun from slipping.

3. When the contact switch is compressed, pull the

trigger of the nail/staple gun, which will result in the

nail/staple being shot out (fig. 5c, step 3).

•

ATTENTION

y

When pulling the trigger, it is necessary to properly

push down the nail/staple gun against the work

surface and when the nail/staple is shot out to hold

it down with sufficient downward force, otherwise

the nail/staple nay not be properly driven into the

material as a result of a loss of impact force when

the nail/staple gun is kicked off the work surface.

4. Lift the nail/staple gun off the surface of the workpie-

ce and move it to the required loca-

tion where the nail/staple is to be

driven and drive in the nail/staple

according to the procedure descri-

bed above.

y

The drive depth can be set using the

control knob (fig. 1, position 9) as

necessary, and a practical test can be

performed on a piece of sample

material.

Fig. 5a

1.

Fig. 5b

2.

Fig. 5c

3.

(1

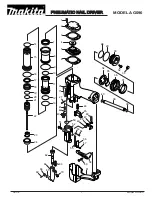

USING THREE COMPONENTS

• Oil lubricator

(8865102)

• Pressure regulator with pressure gauge

(8865103)

• Filter

(8865101)

(2

USING TWO COMPONENTS

• Oil lubricator

(8865102)

• Pressure regulator with pressure gauge

and filter

(8865104)

(3

USING ONE COMPONENT

• Pressure regulator with filter and oil lubricator

(8865105)

Possible methods of connection

The required mixtures of air and pneumatic oil with the correct pressure can be

achieved using three different methods according to diagram 1)-2)-3) with the

specified order of the individual components, which must be adhered to:

(1

(2

(3

8865105

8865102

8865102

8865103

8865101

8865104

Pressure regulator

enables

air pressure to be set

correctly, which is essential

for the optimal and safe

operation of the pneumatic

tool.

Filter (condensate separator)

removes water

(condensate) from compressed air, which forms in

the compressor as a result of water vapour being

compressed in air. Water inside the tool causes

rapid corrosion of its components.

Oil lubricator

adds pneumatic oil to the current of

compressed air, which then enters into the equipment

where it protects its components against jamming

and rapid wear.

8865040

Fig. 4

y

Thoroughly seal the threaded connections on the

connected elements of the air system using Teflon tape.

•

ATTENTION

y

For lubrication of pneumatic tools and for the oil lubri-

cator (oiler) always use only oil intended for pneumatic

tools, which does not froth, is not aggressive against

sealing elements and which has a special viscosity (sui-

table physical characteristics) for lubricating pneumatic

tools. Using other types of oils, e.g. food grade oil,

motor oil, etc. is forbidden.

•

ATTENTION

y

Prior to connecting the nail/staple gun to the source of

compressed air, inspect the machine thoroughly for any

faults and check that no parts are missing.

y

After connecting the nail/staple gun to the source of

compressed air, first check that no compressed air is

leaking from the air system. In the event that air is lea-

king, turn off the compressor, bleed the pressure of the

air system and seal the location of the leak with tape or

by tightening the connection.