Maintenance

If the oil is at room temperature (about 75°F

(24°C)), fill only to the “COLD” level.

Check Tire Pressures

Service Interval: Every 40 hours

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Check tire pressure in drive tires.

3. Inflate drive tires to 12–14 psi (83–97 kPa).

4. Inflate tires to pressures stated above. Measure

the circumference of each drive tire. Adjust tire

pressures within the above range to try to make

tire circumferences match as closely as possible.

5.

For Serial Nos. 599,999 and Lower:

Check the

tire pressure in the pneumatic front caster tires.

Adjust the tire pressure to 16 psi (110 kPa).

Note:

Front caster tires have permanent tire

sealant installed.

For Serial Nos. 600,000 and Higher:

Semi-pneumatic caster tires do not need to be

inflated.

Note:

Do Not add any type of tire liner or foam

fill material to the tires.

Excessive loads created by

foam filled tires may cause failures to the hydro drive

system, frame, and other components. Foam filling

tires will void the warranty.

Check Condition Of Belts

Service Interval: Every 40 hours

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Remove the three mower deck belt shields

to check mower primary and secondary belt

condition.

3. Look under engine deck to check the pump drive

belt condition.

4. Check all idler arms to be sure they pivot freely.

Lubricate Grease Fittings

Note:

See chart for service intervals.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lubricate fittings with one to two pumps of

NGLI grade #2 multi-purpose gun grease.

Refer to the following chart for fitting locations

and lubrication schedule.

Lubrication Chart

Fitting

Locations

Initial

Pumps

Number of

Places

Service

Interval

1. Front

Caster

Wheel Hubs

*0

2

*Yearly

2. Front

Caster

Pivots

*0

2

*Yearly

3. Idler

Pivots

(Mower

Deck)

1

2

Yearly

4. Idler

Pivot (Pump

Drive)

2

1

Yearly

5. Hydro

Control

Arm

Support

Bushings

2

2

40 Hours

* See step 3 for special lubrication instructions on

the front caster pivots and the

Lubricate Caster

Wheel Hubs

section for special lubrication

instructions on the front casters wheel hubs.

Number 4 (Idler Pivot (Pump Drive) Located

Under Engine Deck

3. Lubricate front caster pivots once a year. Remove

hex plug and cap. Thread grease zerk in hole and

pump with grease until it oozes out around top

bearing. Remove grease zerk and thread plug back

in. Place cap back on.

25

Содержание TURF TRACER TT23KAEP

Страница 1: ...TURF TRACER TT23KAEP MODEL ONLY For Serial Nos 790 000 Higher Part No 4500 382 Rev A ...

Страница 11: ...Safety 103 2432 103 4935 116 0404 11 ...

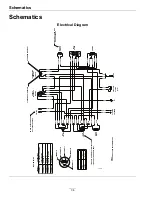

Страница 37: ...Schematics Hydraulic Diagram 37 ...

Страница 39: ...Notes 39 ...

Страница 40: ...Notes 40 ...

Страница 41: ...Service Record Date Description of Work Done Service Done By 41 ...

Страница 42: ...42 ...

Страница 43: ...43 ...