Maintenance

•

Shoulder bolts in ends of speed control crank.

•

OPC lever setscrews.

•

Electric clutch retaining bolt.

•

Pump drive idler pivot bolt.

•

Thumb latch screw threads on handles.

•

Caster wheel spacer nuts.

•

Fuel tank bulkhead fitting nuts.

Adhesives such as “Loctite RC/609 or RC/680” or

“Fel-Pro Pro-Lock Retaining I or Retaining II” are

used on the following:

•

OPC lever hubs and cross-shaft

Note:

Care must be used not to bond the

bearing, next to each OPC hub, to the cross-shaft

which could cause binding of the OPC levers and

erratic operation.

•

Fuel tank studs, where studs are inserted into tank.

Mobil HTS Grease (Or

Food-Grade Anti-seize)

Mobil HTS grease (or food-grade anti-seize) is used

in the following locations:

•

Between the cutter housing spindle and bearings.

•

Between the cutter housing spindle and sheave.

•

Under top cutter housing bearing guard.

Copper-Based Anti-seize

Copper-based anti-seize is used in the following

locations:

On threads of Blade Bolts Serial Nos. 540,000 and

Higher. See

Check Mower Blades

section for

instructions.

Dielectric Grease

Dielectric grease is used on all blade type electrical

connections to prevent corrosion and loss of contact.

Adjustments

Note:

Disengage PTO, shut off engine, wait for

all moving parts to stop, engage parking brake, and

remove key before servicing, cleaning, or making any

adjustments to the unit.

Deck Leveling

See

Adjusting the Cutting Height

section in

Operation.

Pump Drive Belt Tension

Self-tensioning - No adjustment necessary.

Deck Belt Tension

Self-tensioning - No adjustment necessary.

Blade Drive Belt Tension

Self-tensioning - No adjustment necessary.

Brake Adjustment

1. Shut off engine and wait for all moving parts to

stop.

2. Disengage the park brake.

3. Remove the hairpin in the park brake linkage.

Turn the linkage in the yoke until there is 3/16

inch (4.8 mm) to 1/4 inch (6.4 mm) clearance

between the park brake tire bars and the tires with

the park brake disengaged. Re-install the hairpin.

Speed Control Linkage

and Neutral Safety Switch

Adjustment

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Move speed control lever (located on console) to

the full forward position and check orientation of

tabs on the ends of the speed control crank, see

Figure 13. These tabs should be pointing straight

down at the 6 o’clock position or slightly forward.

Adjust threaded yoke at the bottom of speed

29

Содержание TURF TRACER TT23KAEP

Страница 1: ...TURF TRACER TT23KAEP MODEL ONLY For Serial Nos 790 000 Higher Part No 4500 382 Rev A ...

Страница 11: ...Safety 103 2432 103 4935 116 0404 11 ...

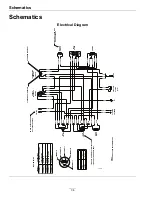

Страница 37: ...Schematics Hydraulic Diagram 37 ...

Страница 39: ...Notes 39 ...

Страница 40: ...Notes 40 ...

Страница 41: ...Service Record Date Description of Work Done Service Done By 41 ...

Страница 42: ...42 ...

Страница 43: ...43 ...