Page 9 of 13

109-4195 Rev. A

16. Reinstall the deck drive belt in the lower groove of

the double sheave. Install plug (Item 40) into

bore of double sheave.

17. Remove the discharge chute from the deck.

Discard the mounting hardware, but save the

discharge chute for use during side discharge

operation. The chute pivot pin (Item 21) and

hairpin (Item 22) may be stored in the pivot holes

on the discharge chute during bagging operation.

Units 600,000 and Higher:

18. Lower the deck fully. Remove the right hand belt

cover. Remove the belt cover mounting stud that

protrudes from the deck. Save the knob for later

use.

19. Remove the blade from the right spindle.

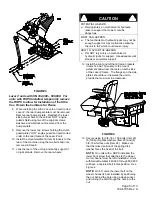

20. Insert special tool 109-2979 into splined end of

spindle shaft.

21. Remove the right sheave nyloc nut, washer, and

splined washer from the spindle shaft. Do not

remove the blade drive sheave. Retain the nut for

later use.

Use special tool 109-2979 to hold spindle from

rotating. Do not use the blade bolt to prevent

rotation.

22. Install the Ultra Vac drive sheave onto the right

spindle shaft. Install the washer that is supplied

with the Ultra Vac drive kit (Item 38) and nut

removed in step 4. Torque the sheave nut to:

5/8-18 Nut (15/16 Hex) 90-110 ft-lbs.

Use special tool 109-2979 to hole spindle from

rotating

(See Figure 10). Do not use the blade

bolt to prevent rotation.

FIGURE 10

Reinstall blade and torque bolt to: For units

with a 1/2-20x2 blade bolt, torque to 50-60 ft-

lbs (75-81 N-m).

23. Reinstall the deck drive belt in the lower

grove of the double sheave. Install plug

(Item 40) into bore of top sheave.

24. Remove the discharge chute from the deck.

Discard the mounting hardware, but save the

discharge chute for use during side discharge

operation. The chute pivot pin (Item 21) and

hairpin (Item 22) may be stored in the pivot

holes on the discharge chute during bagging

operation.

25. Install deflector (Item 46) at the front right

corner of deck as shown in Figure 11. Use

carriage bolt, nut and washer that retains right

corner of adjustable front baffle.

FIGURE 11

26. Install the belt cover mounting stud (Item 27).

For 60” units only, install the spacer (Item

29), two 7/16 spring disk washers (Item 30)

and the plastic knob (See Figure 12). The

knob does not need to be tightened

against the washers at this time.

FIGURE 12

27. Install the mounting pin weldment (Item 18) to

the blower assembly using the 3/8-16 x .75

bolts (Item 28) and whizlock nuts (Item 24).

Maximum deck clearance will be provided if

the bolts are installed from below the