Page 11 of 13

109-4195 Rev. A

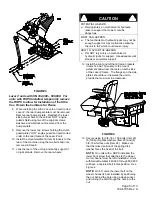

3.

Set deck in lowest cutting position.

4. Slide lower tube onto blower and latch (make sure

that upper tube does not move out of alignment).

5. Drill 7/32 holes in lower tube using upper tube holes

as reference. See Figure 16.

6. Remove tubes from unit and assemble the upper

(Item 2) and lower tubes (Item 3) using (3)

#10-24 x .75 hex washer head screws (Item 4), (3)

#10 washers (Item 6) , and (3) #10-24 nyloc nuts

(Item 5). Screw head should be installed to the

inside of the tube to provide minimum obstruction to

flow. Make sure that the upper and lower ends are

oriented properly as tubes are assembled. (Parting

lines roughly lined up.)

FIGURE 16

7. Slip the upper end of the tube assembly into the

hood opening. Slide the lower end of the tube

assembly over the blower outlet and align the notch

with the tube latch. Latch the tube to the blower.

Install the Weight Plates

All units SN 599,999 and Lower and Liquid

Cooled XS units SN 600,000 and Higher only.

Weight plates not required for air cooled units

SN 600,000 and Higher.

1. The four weight plates (Item 33) must be installed

under the front panel of the floor pan. These

weights give proper balance to the machine when

the removable portions of the bagger are

removed.

Units below SN 600,000 with the 2 post foldable

ROPS installed require additional mounting plates

(Item 42) and a front weight (Item 41) to be

installed. The front weight is removable and

retained by using hairpins (Item 43).

Units SN 439,999 and Lower:

2. Locate the position of the mounting holes. Clamp a

weight plate to the front of the floor pan (See Figure

17). The ears on the weight plate should be

towards the bottom (upside down from the actual

mounted position). Align the bottom edge of the

weight plate with the bottom edge of the floor

pan front panel. Center the weight plate side to

side. Mark the position of all four holes using a

center punch.

3. Drill 3/8 inch holes at the points marked.

FIGURE 17

For units 439,999 and Lower without a ROPS

installed:

4. Install the four weight plates behind the front

panel using the 5/16-18 x 1.50 screws, 5/16

washers and 5/16-18 whizlock nuts (Items 34,

35, and 36). The weight plates will only fit

with the ears located near the bend in the floor

pan (See Figure 18). The decal on the

outside of the floor pan will still be visible with

the weight plates mounted.

FIGURE

18

For units SN 439,999 and Lower with a ROPS

:

5. Install (4) weight plates behind the front panel and

(2) weight mounting plates (Items 33, and 39) as

shown in Figure 16 using (4) 5/16-18 x 2.0

screws, (4) 5/16 flat washers, and (4) 5/16-18

whizlock nuts (Items, 34, 35, and 36).

6. Hook weight plate assembly (Item 42) over the top

of the weight mounting plates and secure with two

hairpins (Item 43) as shown in Figure 19.

Drill holes here