Page 12 of 13

109-4195 Rev. A

Note: The removable weight is heavy. Use

care when lifting. Make sure that you can hold

the weight securely before lifting. Use caution

when positioning your hands so that you do

not set the weight down on your hands or

fingers.

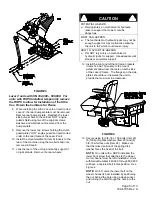

FIGURE 19

For units SN 440,000–599,999:

7. Locate the position of the mounting holes by

aligning the template (P/N 103-5865) on the front

face of the floor pan as shown in Figure 20.

Clamp the template in place. Using a center

punch, mark the positions of the holes on the floor

pan. Flip the template over and repeat on the

other end of the floor pan face.

FIGURE 20

8. Drill 3/8” holes at the points marked.

9. Follow steps 5 through 6 for weight installation

(See Figure17).

For Lazer XS Liquid Cooled units SN 600,000

and Higher:

10. Locate the position of the mounting holes by

aligning the template (P/N 103-5865) on the front

face of the floor pan as shown in Figure 18.

Clamp the template in place. Using a center

punch, mark the positions of the holes on the floor

pan. Flip the template over and repeat on the

other end of the floor pan face.

11. Drill 3/8” holes at the points marked.

12. Install the four weight plates behind the front

panel using the 5/16-18 x 1.50 screws,

5/16 washers and 5/16-18 whizlock nuts

(Items 34, 35, and 36). The weight plates will

only fit with the ears located near the bend in

the floor pan (See Figure 17). The decal on

the outside of the floor pan will still be visible

with the weight plates mounted.

Install the Removable Weights

Note: The removable weights are heavy. Use

care when lifting them. Make sure that you can

hold them securely before lifting them. Use

caution when positioning your hands so that you

do not set them down on your hands or fingers.

1. Assemble the weight brackets (Item 31) to the

removable weights (Item 11) using the 3/8-16

square head bolts (Item 32) and 3/8 whizlock

nuts (Item 25).

Unit 1.5”

Bracket

2.0”

Bracket

Lazer Z AS 60” Units, All

1

1

1

Lazer Z 60” Units,

SN 600,000 and Lower

1

1

1

Lazer Z 60” Units,

SN 600,000 and Higher

Except AS

2

Lazer Z 66” Units,

2

Lazer Z 72” Units

2

Lazer Z XP 60” Units

2

Lazer Z XP 72” Units

2

Lazer Z XS 60” Units

2

Lazer Z XS 66” Units,

2

Lazer Z XS 72” Units

2

1

1.5” bracket is included in Ultra Vac completion

kit 109-1179 or 109-1189.

2. Install the removable weight assemblies over

the caster arms. On some 60” units one

weight has a wide mounting bracket and one

has a narrow bracket. They will only fit the

machine one way. Weights for all other units

are interchangeable left and right.

3. Install a clevis pin (Item 19) and hairpin (Item

20) on each caster weight to retain them.

4. Tighten knob on weight assembly until the

weight is clamped securely to the caster arm.

Align template along

these 3 edges.