EXAMPLE

1000

900

800

700

600

500

400

300

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

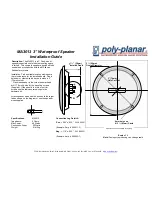

40° 45°

50°

55° 60° 65° 70° 75° 80° 85° 90°

Wipe arc

A

rm

lengt

h (

L)

Wiped area width (W)

Determination of wipe arc

Units in mm

L

D

E

GH

GW

W

H

D = distance top side

glass to center

of spindles

E = eye level

GH = glass height

GW = glass width

H = vertical displacement

L

= length of arm

W = width of wiped area

Pin

Nut for pin

Bearing

Center nut for disc

Retaining ring

Connection lever

Disc

3. Screw M8 center nut for disc onto the motor shaft and tighten properly.

4. Mount the wiper assembly.

5.

Run the motor for a few minutes to check if everything is working correctly.

6. Set the length of the wiper arm, if necessary.

5.4 Rough determination of

wipe arc and wiper blade

With this method the wipe arc and the

wiper blade length can roughly be

determined. Please contact your vendor

to calculate your configuration more

accurately.

• Determine length of pantograph arm

(L): L = E + D

• get the maximum wiped area width

(W): W = ±0.9 * GW

• find the intersection of L and W in the diagram below;

• the wipe arc-line closest to the intersection, shows the wipe arc;

13