9

SCHEDULED MAINTENANCE

4 •

The following items must be check ed during scheduled maintenance:

A • Check and clean the screen of the water solenoid (63) valve.

B • Clean the gas condenser (25).

C • Clean the plastic trough (35) and the trough's water sensors (55 and 67).

D • Clean the ice tank (6), checking for incrustation or blocking, both in the draining tray and the tank's drain (6).

E • Check if the machine is leveled.

F • Check if the fan blade (24) rotates freely and if it is well balanced (there should be no vibrations when it is

operating).

G • Check if the finned axis (50) rotates freely , also observing gaps in the finned axis' bearings (41). (see p. 30

item 3.3)

H • Check the water level in the plastic trough (35). The level determines the size of the ice cubes. If you want to

increase or decrease cube size, verify item 3, sub-item 3.2, failure management, p. 30 (Adjustment of water level

and ice cube height) contained in this manual.

I • Check the wear of the sintered bronze bushings (32) on the plastic trough (35).

J • Check the filtering cartridge. When replaced, it should be by the same or similar model, in order to reduce the

corrosive effect of chlorine on the stainless steel, as well as ensuring the best quality of ice produced.

Before starting maintenance, unplug the machine and remove the machine's cover (1), except for

the EGC-150MA model.

For the EGC-150MA model:

Remove the right side plate (16), loosen the fixation screws, open the frontal lid or

the right side plate (16).

1 • Maintenance and cleaning schedules are suggested to keep your equipment in good condition. Cleaning

varies especially depending on the location of the installation, water conditions and the volume of ice produced.

We recommend that maintenance be carried out every 6 months.

2 • The replacement of the power cord should only be carried out by the manufacturer. Authorized Technical

Assistance or a qualified professional, in order to avoid risks for the user and damage to your equipment.

3 • Filtering Cartridge Replacement

.

Your equipment is supplied with an activated carbon filter. The service life of the filter is 6 months and it

depends on the quantity and quality of water passing through the filter cartridge, which aims at retaining

impurities, reducing chlorine, strange odors and flavors in the water, as well as minimizing the corrosive

effect of chlorine on the stainless steel. The filtering cartridge, which is located inside the filter, does not

allow cleaning after saturation, so it should be changed.

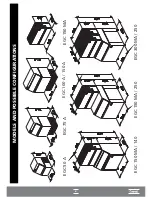

Содержание EGC 100 A / 150 A

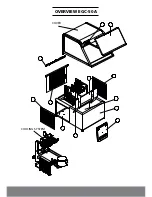

Страница 12: ...OVERVIEW EGC 50A COVER COOLING SYSTEM...

Страница 13: ...OVERVIEW EGC 75A EGC 100A AND EGC 150A In the EGC 150A model there are two compressors and two fans...

Страница 14: ...13 I OVERVIEW EGC 150MA I...

Страница 15: ...14 COOLING SYSTEM EGC 50A EGC 75A EGC 100A AND EGC 150A I COOLING SYSTEM EGC 150MA I...

Страница 16: ...ELECTRICAL ELECTRONIC PART...

Страница 17: ...TROUGH DISPLACEMENT SYSTEM DISPLACEMENT ARM ASSEMBLY TROUGH...

Страница 36: ...35...

Страница 37: ...36 EVEREST REFRIGERA O IND E COM LTDA RESERVES THE RIGHT TO MAKE CHANGES TO ITS EQUIPMENT WITHOUT PRIOR NOTICE...