Issue 2, Nov-98. Applies to software versions 1.3 & 1.4 -9- HA026270

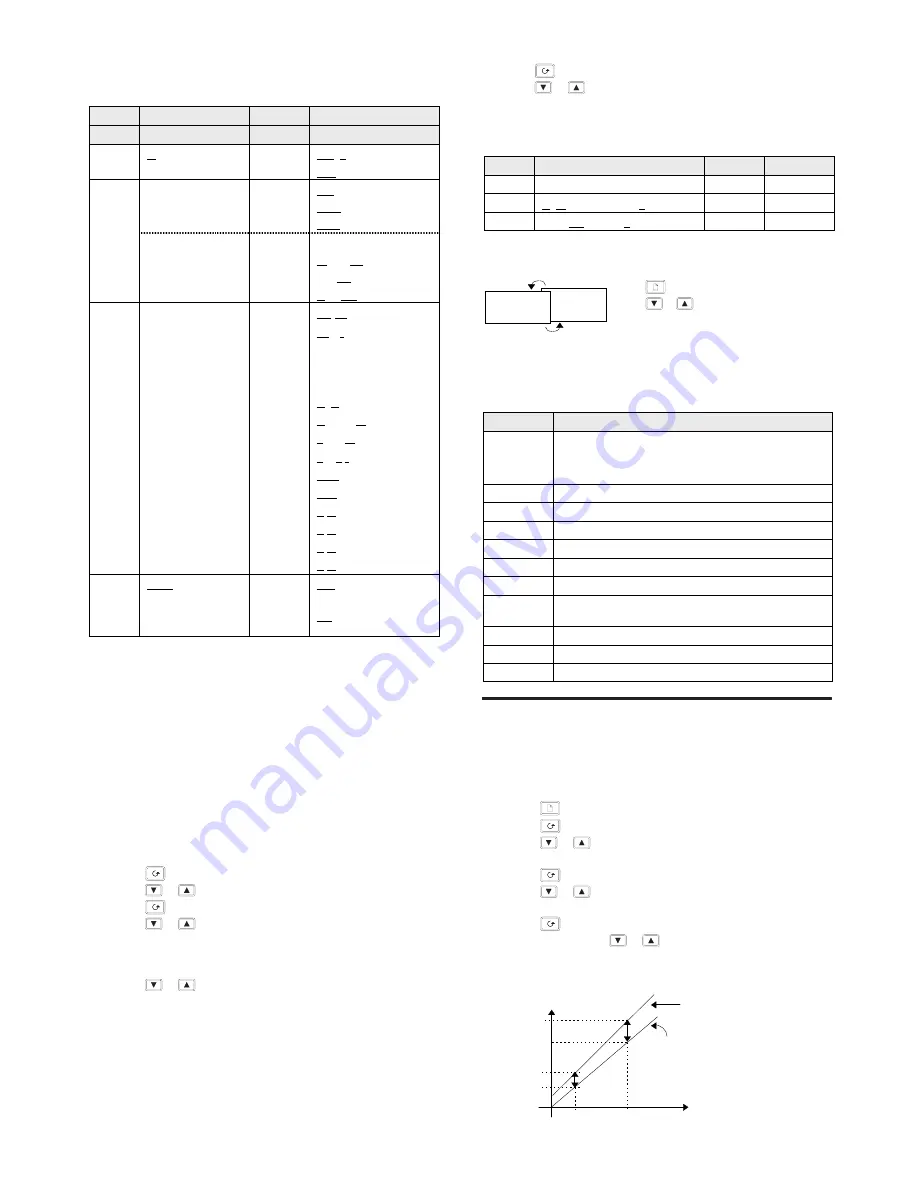

Relay and Logic input/output Configuration

Note: The logic I/O can be configured as an output or a contact

closure input for alarm acknowledge, keylock, or timer run/reset.

Relay output

Options

Meaning

Logic I/O

Identity of output

-

Relay

.

Logic

Function

.

Digital (alarm) output

Heating output

Cooling output

These functions

'

PDSIO mode 1

are only appear

Alarm Acknowledge

Keylock digital input

for the logic I/O

(

Run/reset timer

.

Digital output

)

No change

functions

Clear all alarms

'

Alarm 1

(See note 1)

Alarm 2

(See note 1)

See below: “ To

+

Alarm 3

(See note 1)

Operate the relay

*

New alarm

or logic output

*

Sensor break alarm

from an alarm or

*

Loop break alarm

digital function”

*

Load fail alarm

*

Man mode active

*

End of timing

.'

*

Timer running

.

*

Timer counting down

(See note 2)

.+

*

Timer running

(See note 2)

.#

*

Timer counting down

Sense of the

output

Normal (heating or

cooling outputs)

%

Inverted (for alarms

de-energises in alarm)

* These alarms are always non-latching. Process alarms 1, 2 and 3

are configurable as alarm latching or non-latching, see the ‘

’ List

Note 1: The last three letters will correspond to the alarm type

configured in the

list. If the alarm is disabled, or

or

will be shown.

Note 2:

and

are special functions. If selected, they

illuminate the logic or relay output beacons, OP1 and OP2, without

operating the actual output. They are used to indicate that timing is

in progress while leaving the actual outputs to be operated by the

other digital functions such as the END condition which can be

used to operate an external klaxen.

To Operate the Relay or Logic output from an alarm or

digital function.

1. Press until you reach

2. Press

or

to select

=

3. Press to reach

4. Press

or

to select a alarm or digital function

5.

Leave for 2 seconds. The display returns to

and

connects the selected alarm or digital function to the relay or

logic output.

6. Press

or

again. Two decimal points will appear in the

function that has been added to the output.

Multiple Alarms on one Output

Any number of alarms or digital functions can be added to the

relay or logic output by repeating steps 4, 5 and 6 above. Two

decimal points will appear in those functions that has been added

to the output.

........Continued in the next column

To Clear Alarms from an Output

1. Press

until to reach

2. Press

or

to select

!

3. Leave for 2 seconds. The display returns to

which

disconnects all alarms from the relay.

Passwords

Passwords

Range

Default

Full and Edit level password

/0000

Configuration level password

/0000

User calibration password

/0000

To leave Configuration level

Diagnostic Alarms

In addition to the normal process alarms, the following diagnostics

alarm messages are provided.

Message

Meaning and (Action)

Electrically Erasable Memory Error:

A parameter value has been corrupted.

Contact Eurotherm Controls.

1

Hardware error: ( Return for repair)

Low display range exceeded: (Check input signal)

High display range exceeded: (Check input signal)

'

Error 1: ROM self-test fail. (Return for repair)

Error 2: RAM self-test fail. (Return for repair)

+

Error 3: Watchdog fail. (Return for repair)

#

Error 4: Keyboard failure. Stuck button, or a button

was pressed during power up.

$

Error 5: Input circuit failure. (Return for repair)

Power failure. The line voltage is too low.

23

Tune Error. Appears if auto-tuning exceeds 2 hours.

U

SER CALIBRATION

Your controller has been calibrated for life against known

reference sources. User calibration allows you to apply offsets to

compensate for sensor and other system errors. The parameter

in the list applies a fixed offset over the whole display

range. You may also apply a 2-point calibration as follows:

•

Press

until you reach the

list

•

Press

until you reach the

! parameter

•

Press

or

to enter the password. The factory default is

3.

will be displayed when the correct has been entered.

•

Press

to reach the

! parameter

•

Press

or

, to select

" ( will restore the

factory calibration)

•

Press

to select in turn the four parameters shown in the

graph below. Use

or

to set the desired calibration

points and the offsets to be applied at each point. The

list

on page 5 describes each of the parameters.

Press

to reach the ‘

#’ display

Press

or

to select ‘

*

’ After 2

secs the display will blink and return to

the HOME display in Operator level

.

Factory

calibration

Displayed Value

Factory calibration

User calibration