Issue 2, Nov-98. Applies to software versions 1.3 & 1.4 -10- HA026270

A

UTOMATIC

T

UNING

In PID control, the output from the controller is the sum of three

terms: Proportional, Integral and Derivative. These three terms

deliver just the right amount of power to hold the temperature at

setpoint without oscillation. For stable control, the PID values

must be ‘tuned’ to the characteristics of the process being

controlled. In the 2132 and 2116 this is done automatically using

advanced tuning techniques.

Automatic tuning is performed by switching the output of the

controller On and Off to induce an oscillation in the measured

temperature. From the amplitude and period of the oscillation, the

PID values, shown in the table below, are calculated.

Parameter

Display

Meaning or Function

Proportional

band

The bandwidth in

°

or

°

over which the output

power is proportioned between minimum and

maximum.

Integral time

Determines the time taken by the controller to

remove steady-state error signals.

Derivative

time

Determines how strongly the controller will react

to the rate-of-change of temperature.

Low cutback

The number of

°

or

°

below setpoint at which

the controller will cutback the output power to

prevent overshoot on heat up.

High

Cutback

The number of

°

or

°

above setpoint at which

the controller will increase the output power to

prevent undershoot on cool down.

Relative

cool gain

Only present if cooling has been configured.

Sets the cooling proportional band by dividing the

Pb value by the

value.

If the process cannot tolerate 100% heating or cooling during

tuning, the power can be restricted by the heating and cooling

limits in the Output list. However, the measured value must

oscillate to some degree for the tuner to determine values.

Tuning is normally performed only once during the initial

commissioning of the process. However, if the process under

control subsequently becomes unstable (because its characteristics

have changed), you can re-tune again at any time.

It is best to tune starting with the process at ambient temperature.

This allows the tuner to calculate more accurately.

Heating and Cooling Output Cycle Times

Before commencing a tuning cycle, set the values of

!$!%

(heating output cycle time) and

!$!! (cooling output cycle time)

in the

(output) list.

For a logic heating output (switching a SSR), set

!$!% to & sec.

For a relay output, set

!$!% to && sec.

For a logic cooling output used to control a solenoid valve, set

!$!! to & sec.

Tuning procedure

1. Set the setpoint to the value at which you will normally operate

the process.

2. In the ‘

’ list, select ‘'

’

and set it to

‘

’

3. Press the Page and Scroll buttons together to return to the

HOME display. The display will flash ‘

'’ to indicate that

tuning is in progress.

4. The controller will induce an oscillation in the temperature by

turning the heating on and then off.

5. After two cycles of oscillation the tuning will be completed

and the tuner will switch itself off.

6. The controller will then calculate the tuning parameters and

resume normal control action.

If you want ‘Proportional only’ or ‘P+D’ or ‘P+I’ control, you

should set the ‘

’ or ‘’ parameters to before

commencing the tuning cycle. The tuner will leave them off and

will not calculate a value for them.

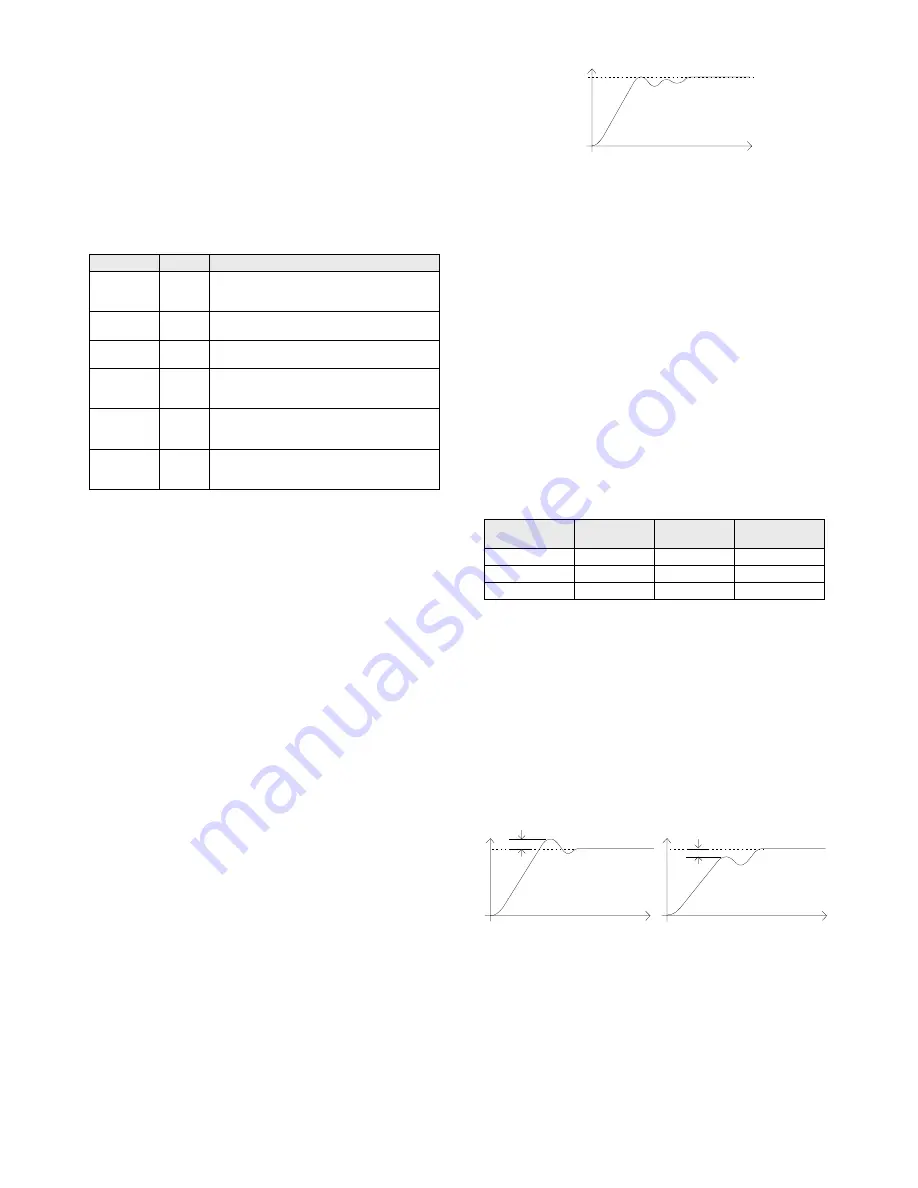

Typical automatic tuning cycle

Calculation of the cutback values

When low cutback or high cutback is set to ‘

(’ their values

will be fixed at three times the proportional band, and will not be

altered during automatic tuning. If set to any other value, they will

be calculated as part of the tuning process.

MANUAL TUNING

If for any reason automatic tuning gives unsatisfactory results, you

can manually tune the controller.

Proceed as follows:

With the process at its normal running temperature:

1. Set the Integral Time ‘

’and

Derivative Time ‘

’ to .

2. Set

High Cutback ‘

%)’ and Low Cutback ‘)’, to ‘’

3. Ignore the fact that the temperature may not settle precisely at

the setpoint

4. Reduce

the

proportional band ‘

)’ until the temperature just

starts to oscillate. If the temperature is already oscillating,

increase the proportional band until it just stops oscillating.

Allow enough time between each adjustment for the

temperature to stabilise. Make a note of the proportional band

value ‘B’ and the period of oscillation ‘T’.

5. Set the PID parameter values according to the formula below:

Type of control

Proportional

band ‘

’

Integral time

‘

’

Derivative time

‘

’

Proportional only

2xB

OFF

OFF

P + I

2.2xB

0.8xT

OFF

P + I + D

1.7xB

0.5xT

0.12xT

Setting the cutback values

The above procedure sets up the parameters for optimum steady

state control. If unacceptable levels of overshoot or undershoot

occur during start-up or for large step changes in temperature, then

manually set the cutback parameters

) and %).

Proceed as follows:

1. Set the low and high cutback settings to 3 x the proportional

band (that is to say,

) = %) = 3 x *).

2. Note the level of overshoot or undershoot that occurs for large

temperature changes (see the diagrams below).

In example (a) increase

) by the overshoot value. In example

(b) reduce

) by the undershoot value.

Example (a)

Example (b)

When the temperature approaches the setpoint from above, you can

set

%) in a similar manner.

Manual reset

When

= manual reset (' ) appears in the +

This parameter sets the output power when the error signal is zero.

It can be manually adjusted to remove steady state error - the

function normally performed by the Integral term.

Time

Temperature

Temperature

Time

Undershoot

Overshoot

Time

Temperature