31

5.2 Facing plate material

1.

Prepare the machine as described in chapter 3

Angle adjustment:

Angle adjustment should be at 0 degrees

Depth adjustment:

It is strongly advised to have the depth adjustment not deeper than (additional) 2 mm per

pass. For example, if you want to face by a depth of 3 mm:

First setting:

2 mm

Second setting:

3 mm

2.

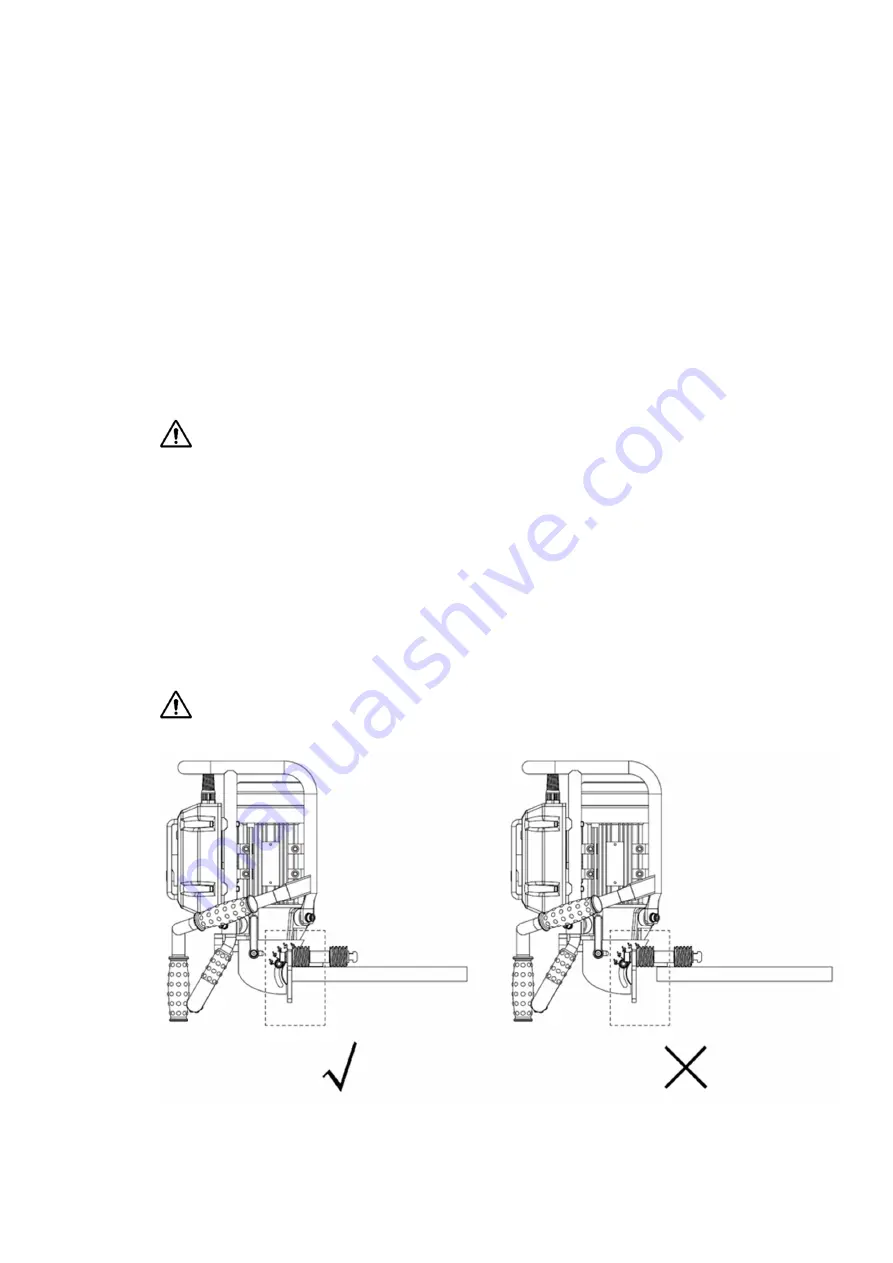

Position the machine vertically on the right (not left) side of the intended bevel

WARNING

Do not let the milling head touch any material yet!

3.

Adjust the machine and switch on the motor as described in chapter 4

4.

Firmly grip the machine at its available handles with both hands. Keep in mind the machine

should be moved from right to left during operation and potential kick-back from the milling

head touching the workpiece may occur. It is advised to position your hands on the handles

opposite from eachother.

5.

Bring the machine towards the workpiece with running motor, in such a way that all guide

plates and guide rollers touch the workpiece fully and even. The machine starts milling

material from the workpiece.

WARNING

The milling head might provide kick-back when it touches the workpiece.

[image 3-2]

6.

Slowly start moving the machine from right to left, while continuously checking if all guide

plates and guide rollers are still firmly pressed against the workpiece.

Содержание B60

Страница 2: ...2 ...

Страница 4: ...4 ...

Страница 11: ...11 B60 B60S B60S shown image 1 1 image 1 2 ...

Страница 12: ...12 B60 image 1 3 B60S image 1 4 ...

Страница 20: ...20 image 2 3 ...

Страница 39: ...39 8 Exploded view spare part list 8 1 Exploded views B60 ...

Страница 40: ...40 B60 CONTINUED ...

Страница 41: ...41 B60S ...

Страница 42: ...42 B60S continued ...

Страница 45: ...45 8 3 Wiring diagrams B60 ...

Страница 46: ...46 B60S ...

Страница 48: ...48 ...