28

MAINTENANCE

25. If the inside tire and disc wheel assembly was not

removed, inflate the tire to the proper pressure.

Checking Tightness on Mounted Dual Disc

Wheels

Check the flange nut, torque after the first 50-100

miles of service. Tighten the nuts as shown in Figure

14.

Hubs

Hub Removal

Demountable disc wheels must be removed before

removing hubs. Support the hub assembly prior to re-

moval. The hub and drum are removed as an assembly

using the following procedure.

1. Loosen the brake adjustment by turning the ad-

justing screw on the slack adjuster.

2. Remove the hub.

3. Bend the flap or tang of the lockwasher from the

flat of the outer spindle nut.

4. Remove the outer spindle nut, two (2) lockwash-

ers and the inner spindle nut.

5. Pull the hub and drum assembly carefully to avoid

damage to the bearing, spindle and inner seal. Catch

the bearing cones as the hub is removed from the

spindle.

Inspection and Cleaning

While the hub is removed, inspect the condition of

the brake drum and linings. Also check the condition

of the cups, cones, seal and axle ring.

Preparing Bearing for Assembly

Coat the bearing cones and cups with oil prior to

assembly.

Hub Installation

After the parts have been cleaned, inspected and

bearings oiled, install as follows:

1. Assemble the inner cone and seal into the hub.

2. Place the hub over the spindle, being careful to

avoid damage to the spindle, seal and brake.

3. Put the outer cone into position.

4. Tighten the inner spindle nut while rotating the

hub both directions until a slight bind is felt.

5. Loosen the nut 1/4 turn. The hub must rotate freely.

6. Install the inner nut lock and place the outer lock-

washer on the spindle.

7. Tighten the outer nut.

8. The end play must be .001 in. (.0254 mm) to .010

in. (.254 mm).

9. Lock the outer spindle nut in place by bending

the tangs or edge of the lockwasher over one flat on the

outer nut.

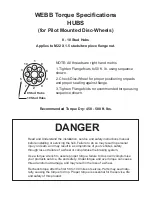

Figure 23. Checking Oil Level in Hub

10. Install the hub cap gasket and hub cap. Fill the

hub to the "Full" line on the hub cap window (see Fig-

ure 13 & Figure 23).

11. Adjust the brakes.

Air Systems and Brakes

Air Systems and Brakes - General

This section contains a description of the operation

of the trailer brake air supply system.

Also included in this section are test instructions,

disassembly and assembly procedures and a trouble-

shooting guide.

Air System Tests

A series of tests must be run daily before operating

trailers with air brakes.

1. Connect the air lines, turn on the air, and pressur-

ize the system. The system must hold 100 PSI (7 Bar)

pressure minimum.

2. Apply the brakes. Inspect the brake action on all

the wheels for proper application.

3. Release the brakes. The brakes must release

promptly. Air pressure must discharge quickly from the

relay emergency valve.

4. Disconnect the emergency line from the trailer.

The trailer brakes must automatically apply.

OIL LEVEL