13

ROUTINE MAINTENANCE

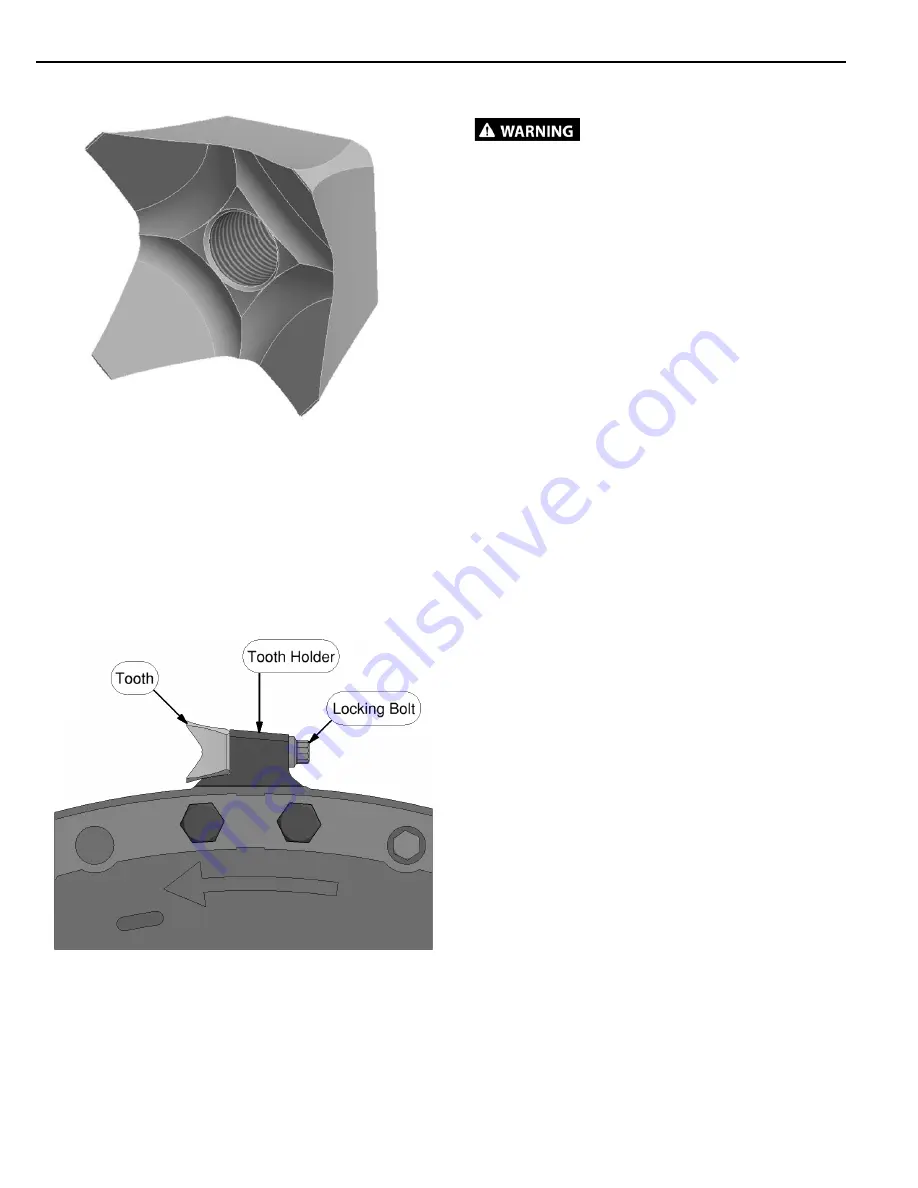

Four-point tooth

Four-Point Tooth Removal

New and used teeth can be sharp.

Wear gloves to protect your hands.

1. Make sure lead hoses are disconnected from

loader before working on attachment. Connect

the attachment hydraulic couplers together if you

want to turn the disc by hand.

2. Remove the tooth locking bolt and tooth, and

set aside.

NOTE:

Tooth may fall from the holder when

removing the tooth locking bolt. Always support

the tooth while removing the bolt.

3. Continue to do this in a directional manner until all

the teeth are removed from the disc.

4. Once all the teeth are removed from the disc,

inspect the disc and holders for excessive wear or

cracking.

NOTE:

Check that the disc can turn freely. Also

check teeth, mounting hardware, and disc for

wear, cracking, or breakage, which can cause

excessive vibrations. Replace if damaged.

Four-Point Tooth Installation

1. If replacing teeth, always use a new bolt during

assembly.

2. Apply anti-seize compound to the bolt threads.

3. Insert tooth locking bolt through tooth holder, and

thread into tooth. Make sure to install the teeth on

the front side of the tooth holders to ensure proper

operation.

4. Tighten the bolt to 350 ft. lbs. (475 Nm) of torque.

5. Repeat procedure until all teeth have been

replaced.

NOTE:

If a few of the teeth are damaged and a

small vibration occurs, it is sometimes possible to

rearrange the teeth to reduce the vibration. This

is done by putting equal amounts of broken teeth

on opposite sides of the disc. A small amount of

vibration is acceptable and normal.

Always use

genuine Erskine

replacement teeth.