4

Improper operation can cause serious

injury or death.

Pre-operation

•

This attachment is designed for mowing grass,

brush and small saplings only.

NEVER

use this

machine for any other purpose.

•

Read the operator

’s manual for the “Skid Steer

Loader

.”

NEVER

allow untrained people to

operate.

•

Operating instructions must be given to everyone

before operating this attachment and at least

once a year thereafter in accordance with OSHA

regulations.

•

NEVER

exceed the maximum recommended

input power or speed specifications for the

attachment. Over-powering or over-speeding the

attachment may cause personal injury and/or

machine damage.

•

Keep all shields, guards, and covers in place.

•

Do not modify equipment or add attachments that

are not approved by Erskine Attachments LLC.

•

Use adequate safety warning lights and devices

as required by local regulations. Obey all local

laws

and

regulations

regarding

machine

operation on public property.

Operation

•

To protect the operator from debris and cab

intrusion, loader must have polycarbonate or

similar strength door and door must be closed in

order to operate the attachment.

•

Hydraulic connections may be hot after use. Use

gloves if connecting or disconnecting after use.

•

Check and be sure all operating controls are in

neutral before starting the engine.

•

Keep people away from loader, attachment and

discharge when in use. This attachment sends

objects flying and has rotating parts.

NEVER

direct discharge toward people

– rocks and

debris can be thrown hundreds of feet.

SAFETY

Operation (continued)

•

NEVER

operate near embankments or terrain

that is so steep that rollover could occur.

•

Always stay in the operator position when using

the attachment.

•

Before leaving the operators position, disengage

hydraulic drive, lower the attachment to rest flat

on the ground, stop engine, set park brake, and

wait for all motion to stop.

•

NEVER

place hands in the discharge area or

clear debris while engine is running.

Avoid High Pressure Fluids Hazard

•

Escaping fluid under pressure can

penetrate the skin causing serious

injury.

•

Avoid the hazard by relieving the

pressure

before

disconnecting

hydraulic lines.

•

Use a piece of paper or cardboard, NOT BODY

PARTS, to check for suspected leaks. Wear

protective gloves and safety glasses or goggles

when servicing or performing maintenance on

hydraulic systems.

•

If an accident occurs, see a doctor immediately.

Any fluid injected into the skin must be

surgically removed within a few hours or

gangrene may result.

Maintenance

•

NEVER

make adjustments, lubricate, clean, or

perform any service on the machine while it is in

operation.

•

Make sure the attachment is serviced on a daily

basis. Improper maintenance can cause

serious injury or death in addition to damage to

the attachment and/or your equipment.

Содержание 66 V4

Страница 17: ...17 BOLT TORQUE INFORMATION ...

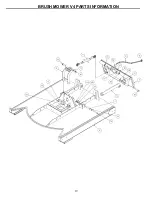

Страница 19: ...19 BRUSH MOWER V4 PARTS INFORMATION ...

Страница 22: ...22 BRUSH MOWER V4 PARTS INFORMATION ...

Страница 28: ...28 P N 350529 A Date Printed 9 23 2022 Erskine Attachments LLC Printed in U S A ...