12

ROUTINE MAINTENANCE___________________

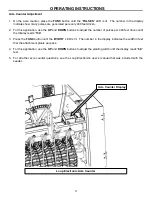

Lower the attachment to rest on the ground, set the park brake, shut down the engine,

remove the key, and wait for all motion to stop before leaving the operator’s seat to perform service of

any kind.

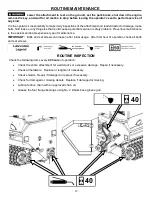

It is the operator’s responsibility to make daily inspections of the attachment and loader/tractor for damage, loose

bolts, fluid leaks, or anything else that could cause a potential service or safety problem. Preventive maintenance

is the easiest and least expensive type of maintenance.

IMPORTANT:

Bolts and set screws can loosen after initial usage. After first hour of operation check all bolts

and set screws.

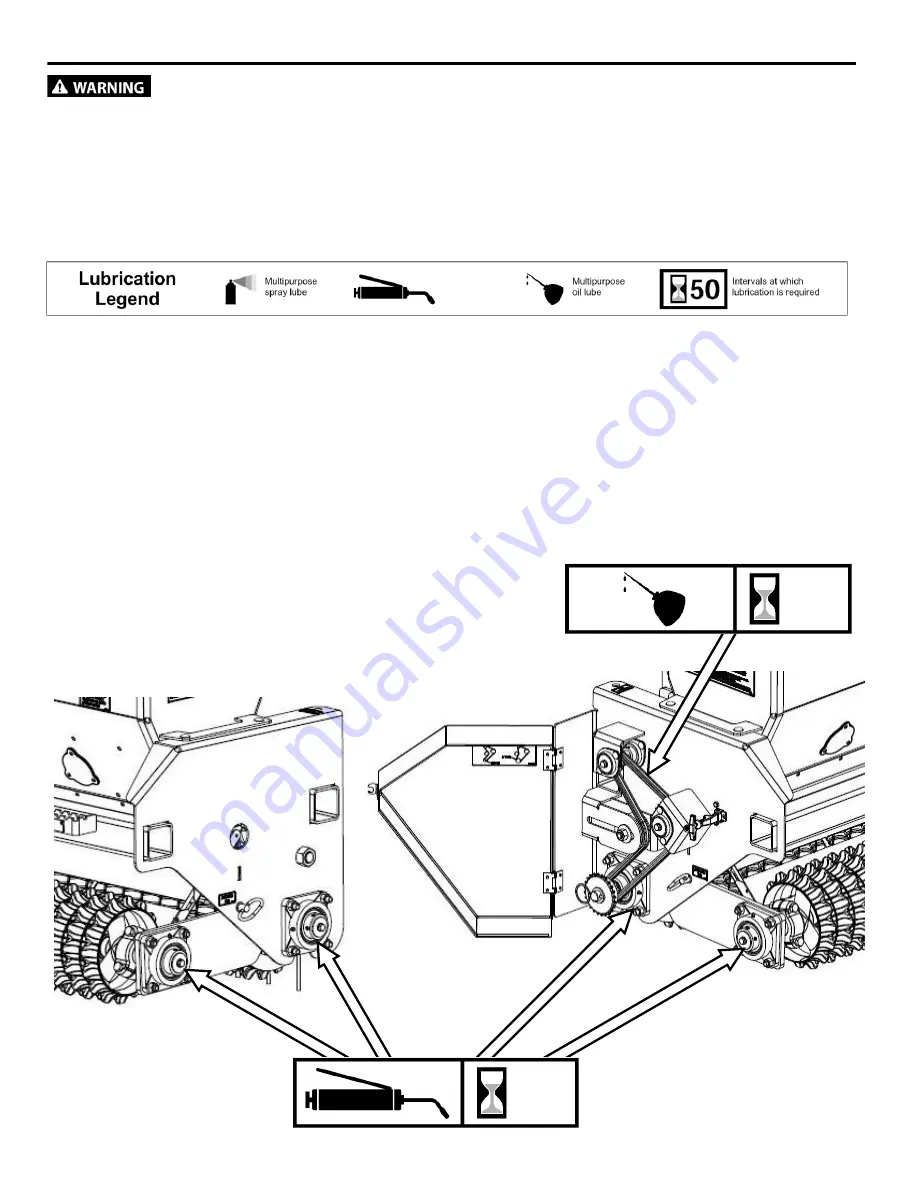

No. 2 Lithium

base gun grease

40

40

ROUTINE INSPECTION

Check the following items every

40 hours

of operation:

•

Check the entire attachment for weld cracks or excessive damage. Repair if necessary.

•

Check all hardware. Replace or retighten if necessary.

•

Check shields. Repair if damaged or replace if necessary.

•

Check for damaged or missing decals. Replace if damaged or missing.

•

Lubricate drive chain with an approved chain oil.

•

Grease the four flange bearings using No. 2 lithium base grease gun.

Содержание 1107080

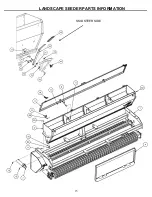

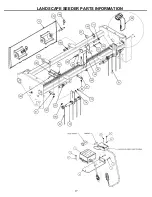

Страница 15: ...15 LANDSCAPE SEEDER PARTS INFORMATION SKID STEER SIDE ...

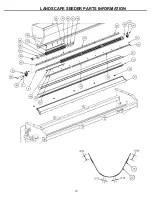

Страница 17: ...17 LANDSCAPE SEEDER PARTS INFORMATION ...

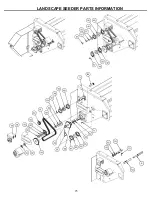

Страница 19: ...19 LANDSCAPE SEEDER PARTS INFORMATION ...

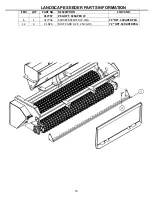

Страница 21: ...21 LANDSCAPE SEEDER PARTS INFORMATION ...

Страница 23: ...23 LANDSCAPE SEEDER PARTS INFORMATION ...

Страница 25: ...25 LANDSCAPE SEEDER PARTS INFORMATION ...

Страница 27: ...27 SEED BOX CALIBRATION CHART ...

Страница 29: ...29 BOLT TORQUE INFORMATION ...

Страница 32: ...32 P N 317688 Date Printed 3 27 2019 Erskine Attachments LLC Printed in U S A ...