TM200 Service Manual

- 20 -

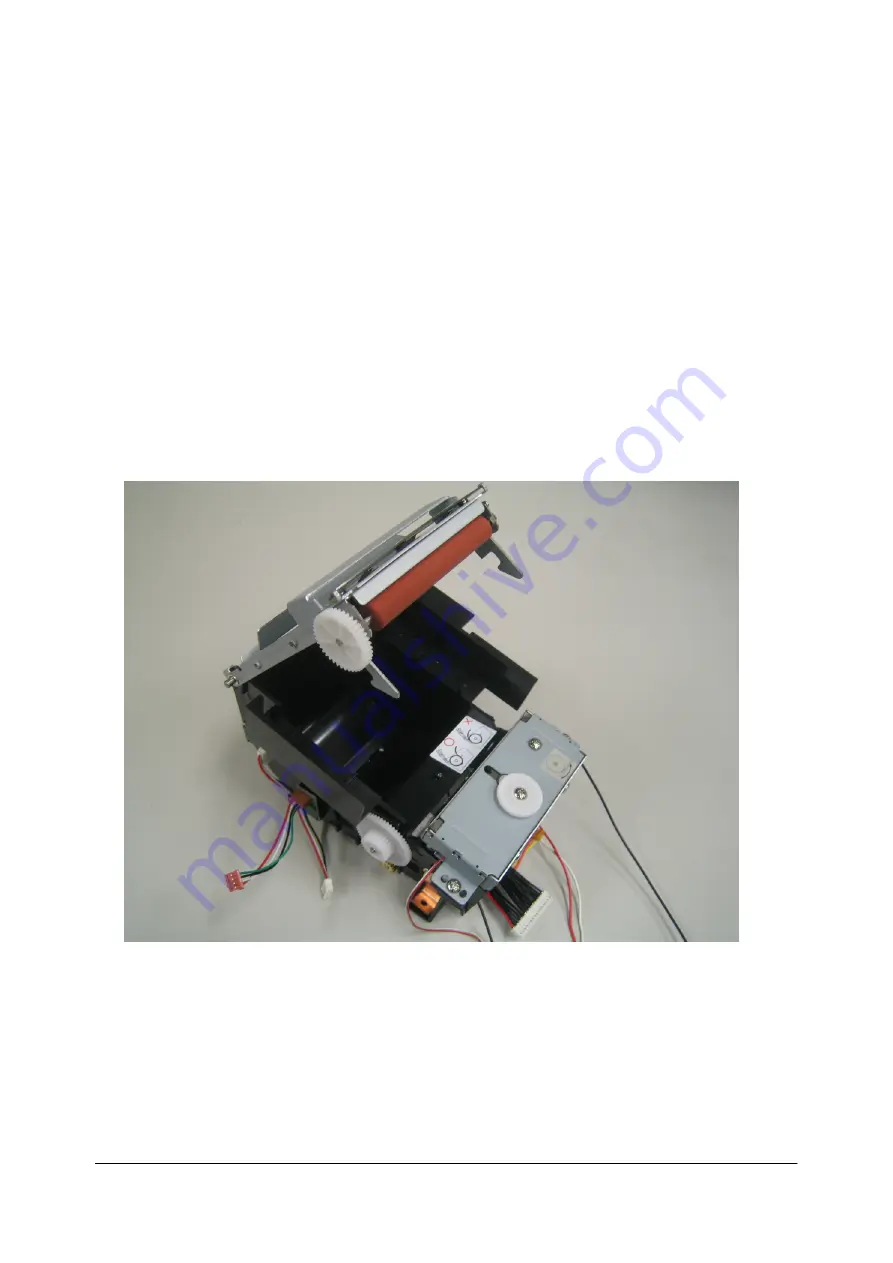

Printer Mechanism

Thermal head Module

The thermal head is designed so its heating element is positioned where it comes into

contact with the platen. The roll paper wrapped around the platen is kept in contact

with the thermal head’s heating element at a prescribed pressure, and printing is

performed when heat is generated by the heating element.

Printing is performed according to the following steps:

1. The print signal sends a prescribed energizing pulse to the electrodes that

correspond to each dot to be printed.

2. Resistors at each electrode generate heat.

3. The heat energy generated by the resistors is transmitted to the roll paper surface

through the protective layer to the paper’s heat-sensitive layer, causing coloration

of the paper.

Figure 2.2 Frame cover open

The paper outlet of the printer is covered, and even if paper output becomes blocked for

some reason, there is enough room in the space between the platen and frame cover for

accumulation of two or three normal length receipts (the length of one sheet is assumed

to be 80mm or less). This reduces the chance of receipt paper becoming bent and of the

print pitch becoming uneven. Paper that accumulates can be easily pulled out of the

printer after the paper outlet is opened.