Stylus C40UX/C40SX/C20UX/C20SX

Revision B

Adjustment

Overview

94

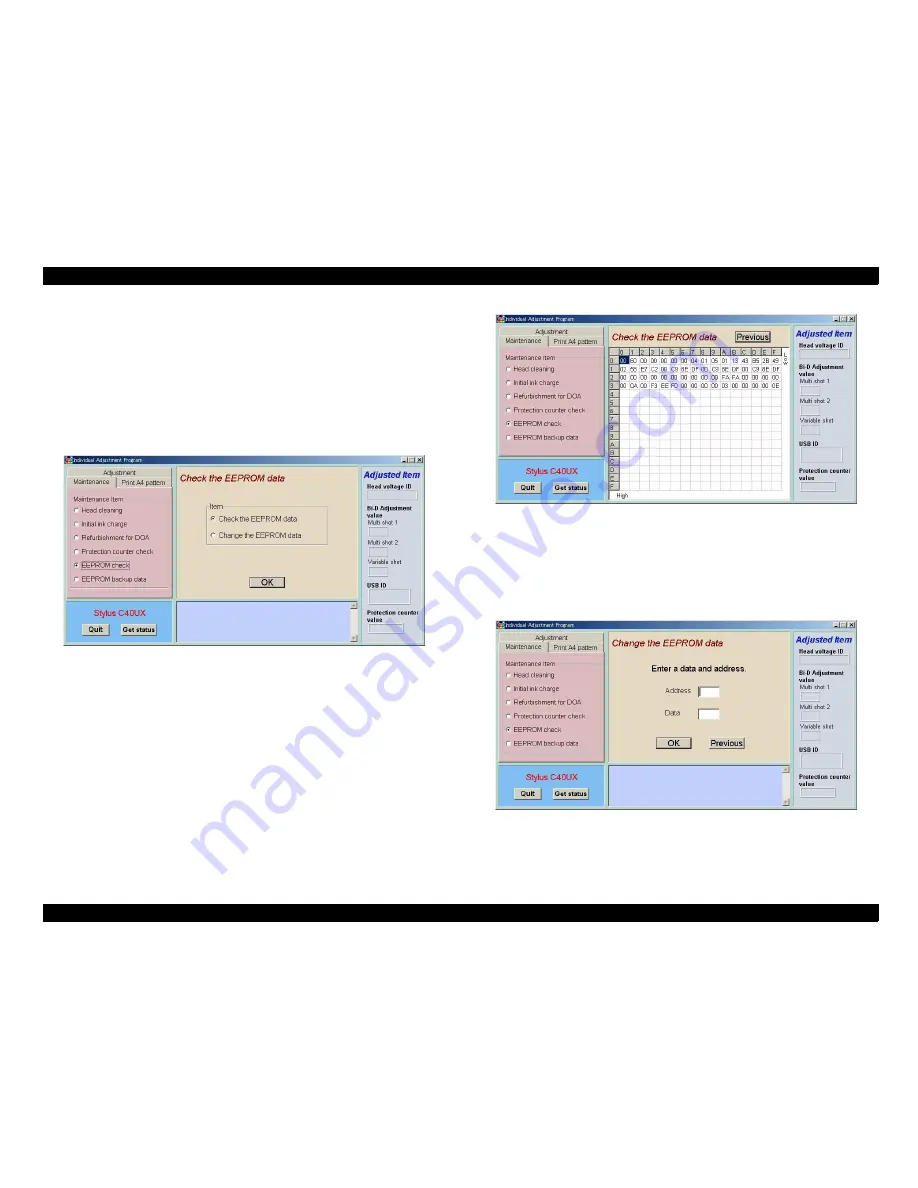

5.1.13 EEPRON check

You can check the EEPROM data or can write the specific data into the specific

address of the EEPROM directly even if the printer is error condition. (In case one of

the main logic circuit such as CPU, I/F receiver IC, RAM, EEPROM is broken, this

function is not available) Select the “EEPROM check” function in the Maintenance

menu.

The main menu of this function is as following figure. The following two functions are

built in this program.

Figure 5-26. EEPROM check function

Check the EEPROM data

You can check the specific data stored in the specific address of the

EEPROM.

Input the specific address with hexadecimal code. Use this function in your

analysis usefully.

Figure 5-27. Check the EEPROM data

Change EEPROM data

You can change the specific data stored in the specific address of the

EEPROM.

However, do not use this function except the special case. Careless usage

causes any trouble.

Figure 5-28. Change the EEPROM data

Содержание Stylus C40UX

Страница 1: ...StylusC40UX C40SX C20UX C20SX Color Inkjet Printer SEIJ01002 SERVICE MANUAL ...

Страница 8: ...C H A P T E R 1 PRODUCTDESCRIPTION ...

Страница 24: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Страница 44: ...C H A P T E R 3 TROUBLESHOOTING ...

Страница 56: ...C H A P T E R 4 DISASSEMBLYANDASSEMBLY ...

Страница 78: ...C H A P T E R 5 ADJUSTMENT ...

Страница 97: ...Stylus C40UX C40SX C20UX C20SX Revision B Adjustment Overview 97 Figure 5 32 A4 Check pattern ...

Страница 98: ...C H A P T E R 6 MAINTENANCE ...

Страница 103: ...C H A P T E R 1 9 7 APPENDIX ...

Страница 120: ......

Страница 121: ......

Страница 122: ......

Страница 123: ......

Страница 124: ......

Страница 125: ......