15

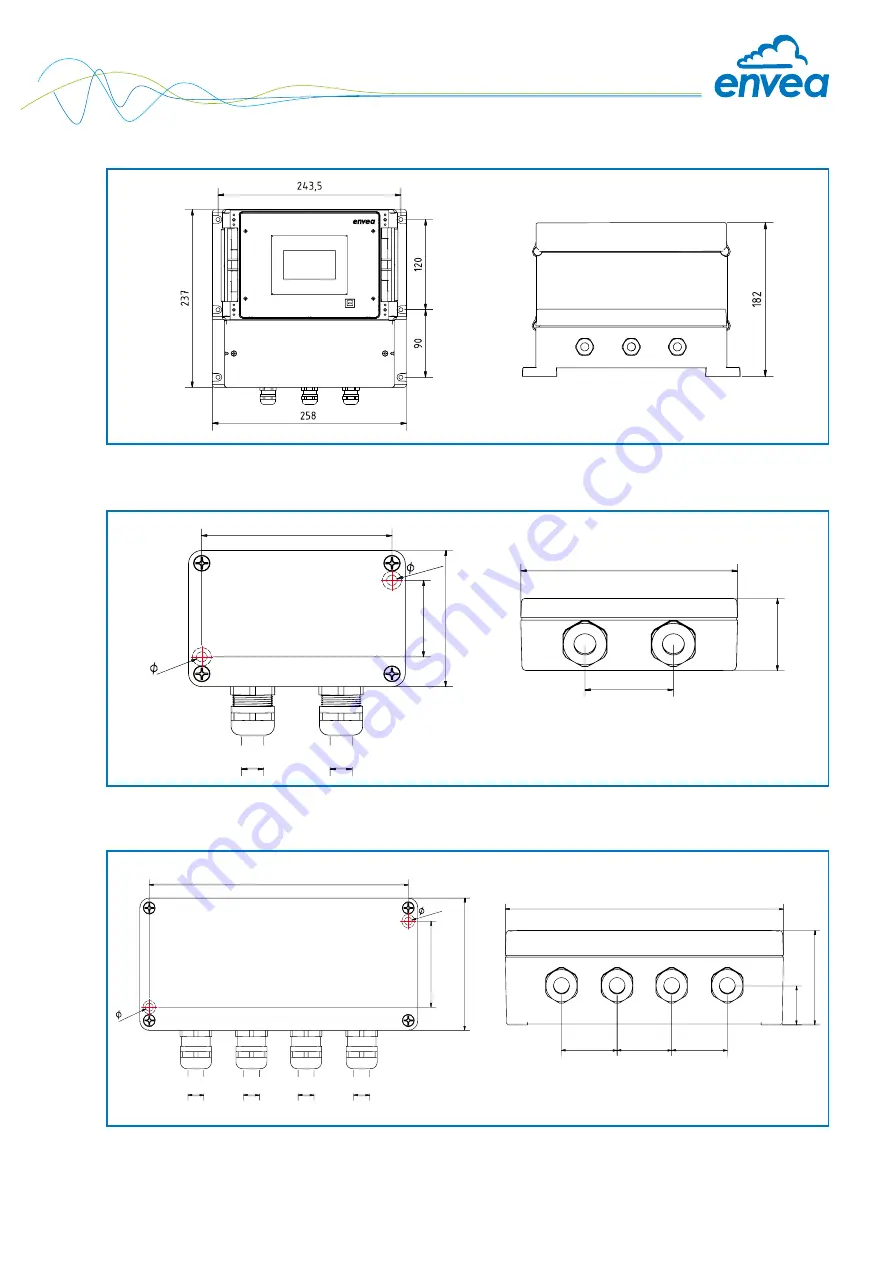

Fig. 10: Dimensions C1 box

Fig. 11: Dimensions C3 box

max.

13 mm

max.

13 mm

50 mm

125 mm

113 mm

52 mm

80 mm

57 mm

4,8 mm

4,8 mm

5 m

m

163 mm

175 mm

35 mm

35 mm

35 mm

23,5 mm

57 mm

52 mm

80 mm

max.

13 mm

max.

13 mm

max.

13 mm

max.

13 mm

5 mm

Fig. 9: Dimensions of the MSE 300-FH