High Temperature Refrigerated Air Dryers

Safety Instructions

When using air compressors and

compressed air accessories, basic safety

rules and precautions must always be

followed, including the following:

READ ALL INSTRUCTIONS FULLY.

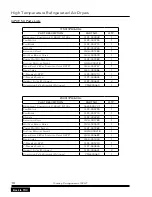

Wiring & Breakers

Wiring, breakers and other electrical

equipment must conform to local and

national electrical codes. Do not operate

this unit with damaged wiring or after

the unit or air handling parts have been

dropped or damaged in any manner.

Notify authorized service facility for

examination, repair or other adjustments.

Warning!

Comply with the National Electrical

Code, Federal, State and Local Codes

when installing or operating this unit.

COALESCING OIL FILTER (OPTIONAL)

– CHANGING AND REMOVING

Shut off power and discharge all pressure

from this unit and air system before

removing or adding parts or attachments

and before maintaining unit.

INSPECT HOSES

Regularly inspect hoses and load handling

fittings for signs of damage, deterioration,

weakness or leakage. Do not use if a

defect is found. Remove dryer from

service and repair or discard defective

parts. Keep hoses away from sharp

objects, chemical spills, oil, solvents and

wet floors. All of these can damage a

hose.

USE SUITABLE PARTS & ACCESSORIES

Do not use air pressurized accessories

or parts in the air system not suitable

for the maximum air pressure used. Be

sure maximum pressure specified by the

accessory manufacturer is well above the

working pressure of your compressor.

RELEASE AIR PRESSURE SLOWLY

Fast moving air will stir up dust and debris,

which may be harmful. Release air pressure

slowly when depressurizing your system to

avoid bodily injury.

SECURE DRAIN LINES

Fasten drain lines to floor or drain.

Pressurized air may periodically pass

through drain lines, which will cause an

unsecured line to whip and may cause

bodily injury.

Warning!

Air from compressor and from Models

QPHT 25, 50, 75, 100 and 125 High

Temperature Refrigerated Dryers,

as equipped, is not safe for human

respiration (breathing).

To provide safe, breathable air,

compressor must be capable of producing

at least Grade D breathing air as

described in Compressed Gas Association

Commodity Specification G7.1-1966.

Special filtering, purifying and associated

alarm equipment must be used to convert

compressed air to “Breathing Air.” Other

special precautions must also be taken.

Refer to OSHA 29 CFR 1910.134.

READ THESE INSTRUCTIONS

THOROUGHLY BEFORE USING THIS

UNIT.

2

Quincy Compressor-QPHT

Back to TOC

Содержание Quincy Compressor QPHT 100

Страница 2: ......

Страница 4: ......

Страница 24: ...High Temperature Refrigerated Air Dryers QPHT 25 Dimensional 20 Quincy Compressor QPHT Back to TOC ...

Страница 25: ...High Temperature Refrigerated Air Dryers QPHT 50 Dimensional Quincy Compressor QPHT 21 Back to TOC ...

Страница 26: ...High Temperature Refrigerated Air Dryers QPHT 75 100 125 Dimensional 22 Quincy Compressor QPHT Back to TOC ...

Страница 27: ...High Temperature Refrigerated Air Dryers QPHT 25 Wiring Diagram Quincy Compressor QPHT 23 Back to TOC ...

Страница 28: ...High Temperature Refrigerated Air Dryers QPHT 50 Wiring Diagram 24 Quincy Compressor QPHT Back to TOC ...

Страница 29: ...High Temperature Refrigerated Air Dryers QPHT 75 115V Wiring Diagram Quincy Compressor QPHT 25 Back to TOC ...

Страница 30: ...High Temperature Refrigerated Air Dryers QPHT 75 230V Wiring Diagram 26 Quincy Compressor QPHT Back to TOC ...

Страница 37: ......