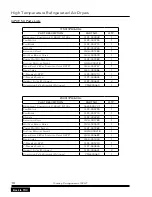

High Temperature Refrigerated Air Dryers

Troubleshooting

S

ymptomS

C

auSe

R

emedy

m

oiStuRe

downStReam

R

efRigeRation

CompReSSoR

not

Running

C

heCk

eleCtRiC

poweR

Supply

.

i

f

Red

light

iS

on

,

Call

foR

faCtoRy

SeRviCe

.

S

uCtion

pReSSuRe

ReadS

above

the

blue

zone

C

lean

the

aiR

Cooled

CondenSeR

(

See

p

age

12).

a

djuSt

hot

gaS

bypaSS

valve

(

See

p

age

12).

C

heCk

foR

defeCtive

fan

motoR

and

ReplaCe

.

m

oiStuRe

SepaRatoR

auto

dRain

malfunCtion

C

heCk

the

auto

dRain

opeRation

(

See

p

age

11).

C

heCk

foR

Clogged

dRain

line

fRom

auto

dRain

outlet

to

flooR

dRain

.

C

heCk

the

eleCtRoniC

timeR

foR

looSe

wiReS

oR

evidenCe

of

buRn

out

.

o

il

downStReam

(o

nly

applieS

with

oil

filteR

option

)

o

il

filteR

malfunCtion

C

heCk

the

dRain

opeRation

.

C

lean

the

dRain

if

StuCk

oR

Clogged

.

C

heCk

the

dRain

manual

valve

foR

Clogging

.

f

ilteR

element

diRty

R

eplaCe

element

(

See

p

age

11).

l

ow

aiR

pReSSuRe

downStReam

S

uCtion

pReSSuRe

below

the

blue

zone

.

t

hiS

CauSeS

fReeze

-

up

in

the

aiR

SyStemS

a

djuSt

hot

gaS

bypaSS

valve

(

See

p

age

12).

l

ow

on

RefRigeRant

. C

all

foR

SeRviCe

.

t

o

ConfiRm

fReeze

-

up

,

Shut

off

the

unit

foR

15

minuteS

. a

iR

pReSSuRe

Should

Come

baCk

to

line

pReSSuRe

.

C

ontinuouS

aiR

flow

thRough

the

moiStuRe

dRain

line

f

oReign

mateRialS

lodged

on

the

valve

Seat

p

ReSS

the

puSh-to-teSt

SwitCh

SeveRal

timeS

.

d

iSConneCt

the

dRain

lineS

to

the

Solenoid

valve

and

blow

CompReSSed

aiR

fRom

outlet

while

pReSSing

the

puSh-to-teSt

SwitCh

.

S

hoRt

-

CiRCuited

timeR

boaRd

R

eplaCe

.

S

hoRt

-

CiRCuited

puSh-to-teSt

SwitCh

R

eplaCe

.

d

efeCtive

Solenoid

valve

R

eplaCe

.

m

oiStuRe

iS

not

dRaining

C

logged

Solenoid

valve

p

ReSS

the

puSh-to-teSt

SwitCh

SeveRal

timeS

.

d

iSConneCt

the

dRain

lineS

to

the

Solenoid

valve

and

blow

CompReSSed

aiR

fRom

outlet

while

pReSSing

the

puSh-to-teSt

SwitCh

.

d

efeCtive

timeR

boaRd

R

eplaCe

.

d

efeCtive

Solenoid

valve

R

eplaCe

.

C

logged

dRain

lineS

C

lean

oR

ReplaCe

.

o

ptional

oil

filteR

not

dRaining

. (o

il

level

Seen

above

half

way

point

thRough

the

bowl

Sight

glaSS

.)

d

efeCtive

dRain

valve

R

eplaCe

.

p

lugged

dRain

valve

C

lean

in

Soap

and

wateR

oR

ReplaCe

.

14

Quincy Compressor-QPHT

Back to TOC

Содержание Quincy Compressor QPHT 100

Страница 2: ......

Страница 4: ......

Страница 24: ...High Temperature Refrigerated Air Dryers QPHT 25 Dimensional 20 Quincy Compressor QPHT Back to TOC ...

Страница 25: ...High Temperature Refrigerated Air Dryers QPHT 50 Dimensional Quincy Compressor QPHT 21 Back to TOC ...

Страница 26: ...High Temperature Refrigerated Air Dryers QPHT 75 100 125 Dimensional 22 Quincy Compressor QPHT Back to TOC ...

Страница 27: ...High Temperature Refrigerated Air Dryers QPHT 25 Wiring Diagram Quincy Compressor QPHT 23 Back to TOC ...

Страница 28: ...High Temperature Refrigerated Air Dryers QPHT 50 Wiring Diagram 24 Quincy Compressor QPHT Back to TOC ...

Страница 29: ...High Temperature Refrigerated Air Dryers QPHT 75 115V Wiring Diagram Quincy Compressor QPHT 25 Back to TOC ...

Страница 30: ...High Temperature Refrigerated Air Dryers QPHT 75 230V Wiring Diagram 26 Quincy Compressor QPHT Back to TOC ...

Страница 37: ......