13

10.2 Periodic Maintenance Chart

Refer to the Periodic Maintenance Chart (Table 1) for a

list of various routine checks and procedures.

10.3 Cleaning

• Clean the cutter using a dry cloth or compressed air.

For plastic surfaces, use a cloth slightly dampened

with water.

NOTICE:

CAUTION

To prevent possible injury, always wear

safety glasses or face mask when using compressed

air.

• Be sure there are no traces of oil, grease or corrosive

substances on the tool, especially on the grips.

• Use a damp cloth and soapy water to clean plastic

components.

• Do not use gasoline or thinner to clean the tool.

10.4 Fasteners

Periodically check all screws, nuts and other fasteners

for proper tightness. Tighten any loose fasteners.

Replace any worn or damaged fasteners. This should

be performed periodically or every day in the event of

frequent or prolonged cutter operation.

NOTICE

Failure to check and tighten fasteners as

required may result in serious damage to the cutter.

10.5 Cutter Hydraulic System

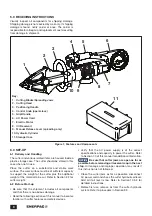

The cutter contains a small hydraulic pump and an oil

reservoir with a rubber diaphragm. The oil level must be

periodically checked and additional oil must be added if

the oil level is low. In addition, the oil must be completely

changed at the specified interval. Refer to the Periodic

Maintenance Chart (Table 1).

Table 1 - Periodic Maintenance Chart

Time Interval

Maintenance Operation

Method

To be performed by:

Every 8 hours of

operation:

Check the cutter for loose,

damaged or worn parts.

Check for oil leaks. Tighten,

replace or repair as required.

Visual

Operator

Clean the cutter exterior.

Refer to instructions in

Section 10.3.

Operator

Check the tightening torque

of screws and bolts. Replace

any missing screws or bolts.

Use torque wrench. Refer to

repair parts sheet for complete

torque specifications.

Operator

Every 1600 hours

of operation:

Change the hydraulic oil.

Refer to instructions in

sections 10.5.1 - 10.5.3.

Service Center

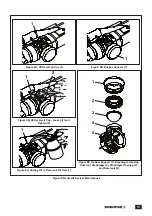

10.5.1 Hydraulic System Maintenance Precautions

NOTICE:

WARNING

Always disconnect cutter from AC power supply

before performing hydraulic system maintenance.

Failure to observe this precaution could result in

accidental start-up while maintenance procedures

are being performed. Serious personal injury and

damage to cutter may result.

Wait for cutter to cool before performing hydraulic

system maintenance. Hot oil can cause burns.

Be sure that oil reservoir cap is securely tightened

after checking oil level or changing the oil. Leaking

oil can cause short circuits, fire and explosions.

Additional Precautions:

• Do not check oil level or change the oil in dusty areas.

• Be sure that all tools (wrench, screwdriver, etc.) used

to perform maintenance procedures are clean.

• When adding oil and performing oil changes, take every

precaution to prevent impurities from contaminating

the oil or entering the cutter. Impurities can cause

permanent damage to the hydraulic components.

• The hydraulic reservoir contains a rubber diaphragm

that slightly pressurizes the oil. Some oil spillage may

occur when checking the oil level or when changing

the oil. Wear and/or use appropriate personal

protective equipment (PPE) to prevent exposure to

hydraulic oil.

• Use only new Enerpac HF hydraulic oil poured from a

clean container. Use of other oil brands and/or used

oil may damage the cutter and may void the Enerpac

product warranty.

Содержание ECSE300

Страница 20: ...WWW ENERPAC COM...