Luba

MD

GL Collector – Technical manual

Version 1.0-EN-January 2012

© Enerconcept Technologies inc.

4

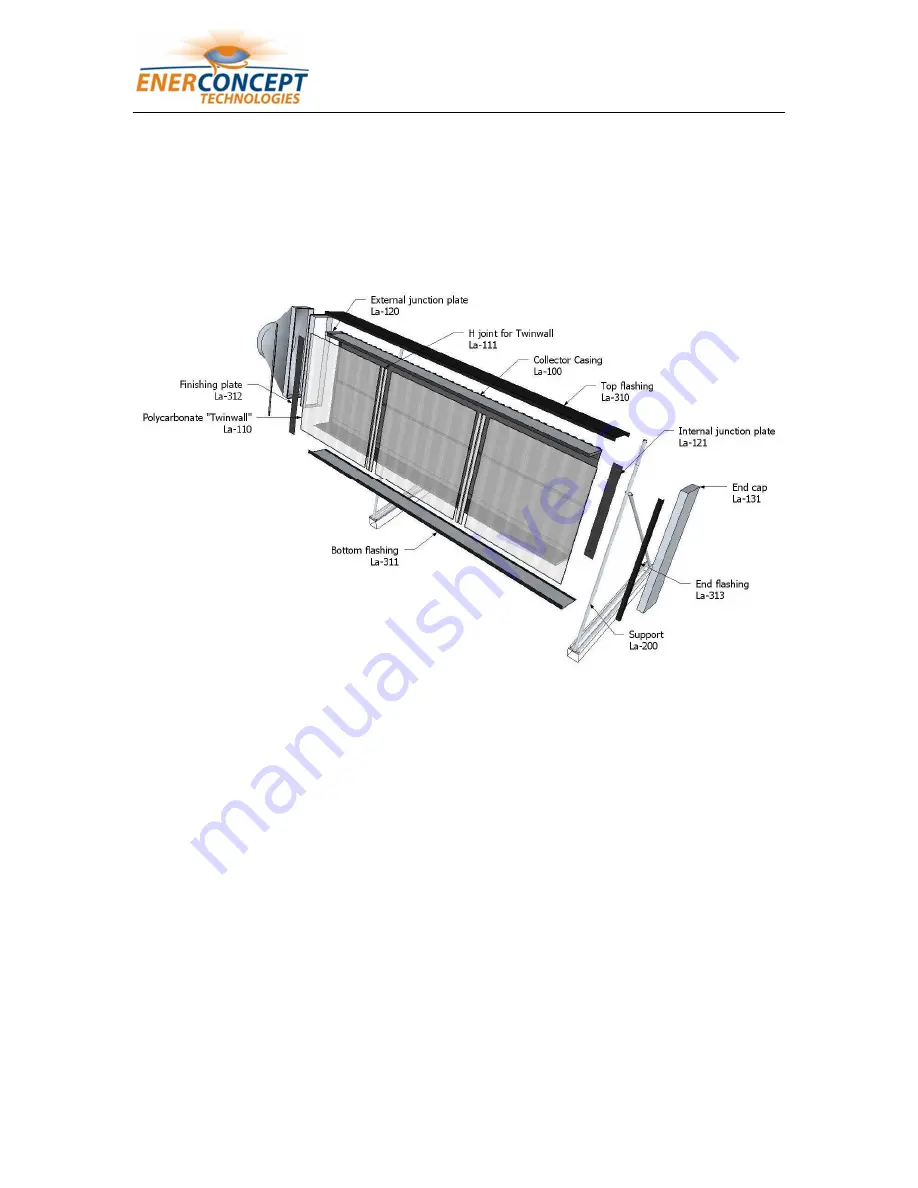

2 Components of the Luba

GL collector

The Luba

GL collector system is remarkable, thanks to its extreme simplicity. It is made of fixed

parts that are maintenance free. Each collector is laterally joined to the next using a pre-installed

junction plate found in every collector with the exception of the end collectors which have an end

cap.

Figure 4 : Exploded view of the Luba

GL collector’s components

2.1 Casing

The casing is made of a 26 gauge perforated black corrugated steel sheeting and two (2) 7"

(178mm) U bars on the top and bottom of the casing. The inside of the casing is covered with a

black felt acting as the absorber.

2.2 Caps

Two caps are required on each of the collector rows set up in series. The first, the joining cap, is

required at the beginning of each row in order to join the collectors to the ventilation ducts on the

roof. The second, or the end cap, is placed at the end of each row of collectors. The airtightness

of the caps forces the air that is taken in by the ventilation system to pass through the collector’s

back perforations.

2.3 Absorber

The Luba

GL collector’s absorber is made of black painted steel perforated on its entire surface

and covered with a black felt fabric. The absorber admits fresh air from the back eliminating the

need for insulation and forcing the heat to be removed from the absorbers surface and entering