Quick Installation Guide

00825-0500-4809, Rev CA

September 2003

Threaded Flo-Tap 485 Annubar

S

TEP

3: I

NSTALL

I

SOLATION

V

ALVE

1. Thread the guide nipple into the mounting.

2. Thread the isolation valve onto the guide nipple. Ensure that the

valve stem is positioned so that when the Flo-Tap is installed, the

insertion rods will straddle the pipe and the valve handle will be

centered between the rods (see Figure 8). (Note: Interference will

occur if valve is located in line with the rods.)

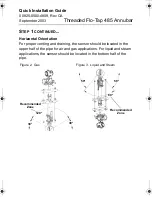

Figure 8. Isolation Valve Orientation

S

TEP

4: M

OUNT

D

RILLING

M

ACHINE

Drilling Machine is not provided with assembly.

1. Determine the sensor size based on the probe width (see Table 2).

2. Mount the drilling machine to the isolation valve.

3. Open the valve fully.

4. Drill the hole into the pipe wall in accordance with the instructions

provided by the drilling machine manufacturer (use Table 2 to

select the proper drill bit for the sensor being used).

5. Retract the drill fully beyond the valve.

Table 2. Sensor Size / Hole Diameter Chart

Sensor

Width

Sensor

Size

Hole Diameter

0.590-in.

(14.99 mm)

1

3

/

4

-in.

(20 mm)

+ 1/32-in (1 mm)

– 0.00

1.060-in.

(26.92 mm)

2

1

5

/

16

-in.

(35 mm)

+

1

/

16

-in. (1 mm)

– 0.00

1.935-in.

(49.15 mm)

3

2

1

/

2

-in.

(65 mm)

+

1

/

16

-in. (1 mm)

– 0.00

Isolation Valve

Pressure

Drilling

Machine

Isolation

valve is fully

closed after

withdrawing

drill

Isolation

valve is

fully open

when

inserting

drill

4809-0500 Rev CA.fm Page 10 Monday, September 22, 2003 11:14 AM