2

Functional Safety Manual

M310/FSM, Rev BA

Introduction

April 2017

Introduction

1.4

Terms, abbreviations, and acronyms

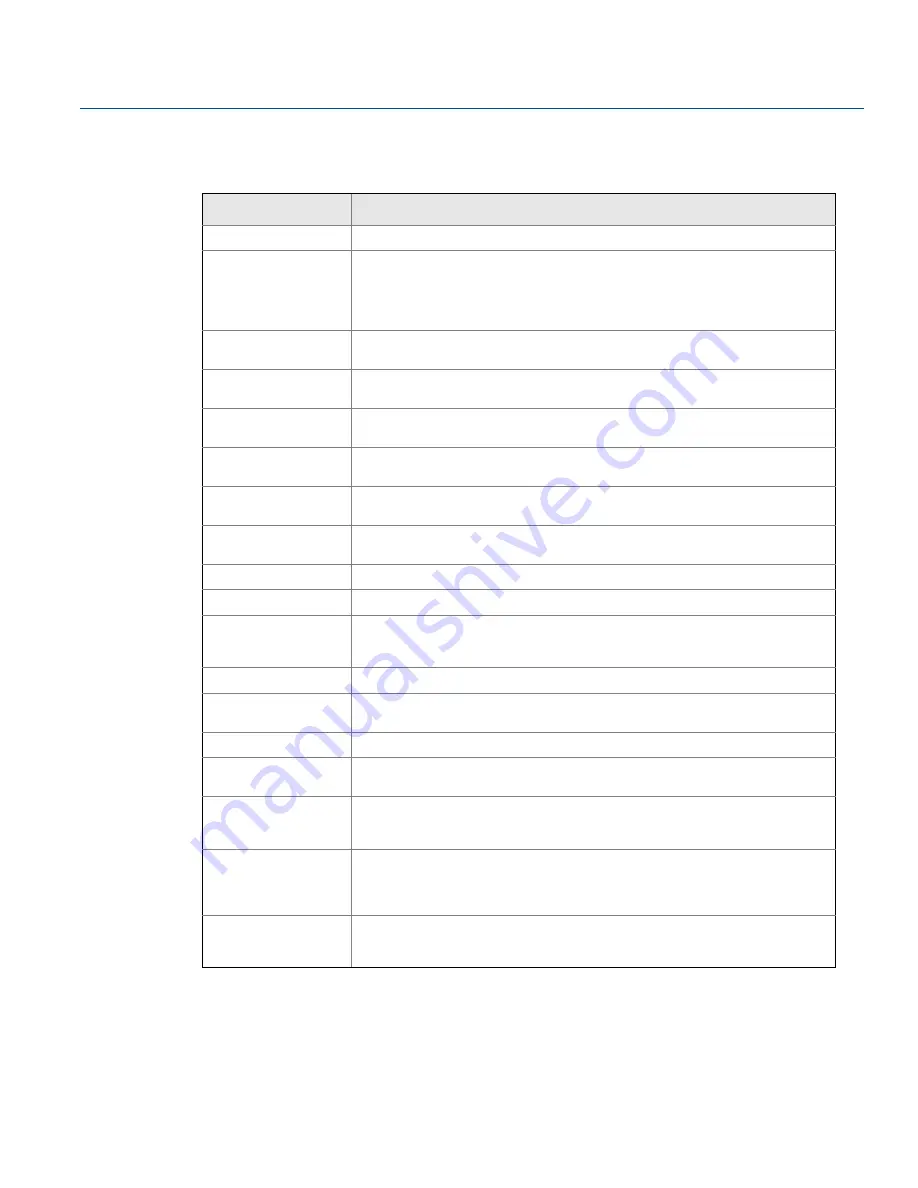

Table 1-1. Terms, Abbreviations, and Acronyms

Term

Definition

Basic safety

Freedom from unacceptable risk of harm

BPCS

Basic Process Control System – a system which responds to input signals from the

process, its associated equipment, other programmable systems and/or an

operator and generates output signals causing the process and its associated

equipment to operate in the desired manner but which does not perform any

safety instrumented functions with a claimed SIL greater than or equal to 1.

Fail Safe State

State where the switch output is in the state corresponding to an alarm

condition. In this condition, the switch contacts will normally be open.

Fail Dangerous

Failure that does not respond to an input from the process (i.e. not switching to

the fail-safe state).

Fail Dangerous

Detected

Failure that is dangerous but is detected.

Fail Dangerous

Undetected

Failure that is dangerous and that is not detected.

Fail No Effect

Failure of a component that is part of the safety function but that has no effect on

the safety function.

Fail Safe

Failure that causes the switch to go to the defined fail-safe state without an input

from the process.

FIT

FIT is the abbreviation for Failure In Time. One FIT is 1x10

-9

failure per hour

FMEDA

Failure Modes, Effects and Diagnostic Analysis

Functional Safety

Part of the overall safety relating to the process and the BPCS which depends on

the correct functioning of the Safety Instrumented System (SIS) and other

protection layers.

HFT

Hardware Fault Tolerance

Low demand

Mode of operation, where the frequency of demands for operation made on a

safety-related system is no greater than twice the proof test frequency.

PFD

AVG

Average Probability of Failure on Demand

SFF

Safe Failure Fraction – a fraction of the overall random failure rate of a device that

results in either a safe failure or a detected dangerous failure.

SIF

Safety Instrumented Function – a safety function with a specified SIL which is

necessary to achieve functional safety. Typically a set of equipment intended to

reduce the risk due to a specified hazard (a safety loop).

SIL

Safety Integrity Level - a discrete level (one out of four) for specifying the safety

integrity requirements of the safety instrumented functions to be allocated to

the safety instrumented systems. SIL 4 has the highest level of safety integrity,

and SIL 1 has the lowest level.

SIS

Safety Instrumented System (SIS) – an instrumented system used to implement

one or more safety instrumented functions. An SIS is composed of any

combination of sensors, logic solvers, and final elements.

Содержание Mobrey Series

Страница 2: ......

Страница 8: ...4 Functional Safety Manual M310 FSM Rev BA Introduction April 2017 Introduction ...

Страница 18: ...14 Functional Safety Manual M310 FSM Rev BA Operation and Maintenance April 2017 Operation and Maintenance ...

Страница 20: ...Proposed Proof test Procedure April 2017 Functional Safety Manual M310 Rev BA Proposed Proof test Procedure 16 ...

Страница 25: ......