9

8 Series

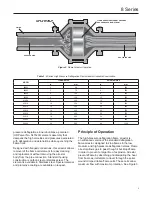

DESCRIPTION

COEFFICIENT OF FRICTION

MULTIPLY TORQUE VALUE IN TABLE 5 BY

Machine Oil

f = 0.15

1.00

API SA2 Grease

f = 0.12

0.80

Never-Seez

®

(Ni base)

f = 0.11

0.73

Never-Seez

®

(Cu base)

f = 0.10

0.67

Molykote

®

G-n Paste

f = 0.06

0.40

Table 6.

Torque

Correction Factors for Common Lubricants

Molykote

®

G-n is a mark owned by Dow Corning Corporation.

Never-Seez

®

is a mark owned by Bostik, Inc.

CAUTION

Element assemblies are heavy and will

require the use of adequate equipment

and manpower to prevent injury.

3. Thoroughly clean the gasket sealing faces being

careful not to damage the sealing surface. For

reassembly, lightly grease one side of a new

gasket and place it in the machined recess of each

interior flange on the two conical sections.

4.

Replace the flame element assembly with a new

assembly or properly cleaned and inspected

existing unit.

5. Loosen the jacking nuts on the tension rods until

the flame cell assembly seats onto the gaskets.

6. Replace all tensioning studs and hand tighten the

outer nuts. Check to be sure that all the jacking

nuts are completely loose and not making contact

with the flange face.

7. Torque the bolts in sequence as shown in

Torquing Instruction.

Torquing Instruction

CAUTION

Excessive or uneven torquing can

cause permanent damage to gaskets

and housing.

Tools/Supplies Required

• Hand operated conventional torque wrench or

power assisted torque wrench appropriate for the

specified torque.

•

Socket wrenches of the proper size to fit the hex

nuts being tightened

•

Molydisulfide based lubricating paste,

Molykote

®

G-n or equivalent

• Brush suitable for applying lubricant to the studs

• Wiping rags necessary for the clean up of

excessive lubricant

Procedure

1. Use studs and nuts that are free of visible

contamination and corrosion.

2. Apply lubricant to the threads of the stud

protruding outboard of the interior flanges and

to the face of the hex nuts which will contact

the flange.

3. Assemble the nuts to the studs such that the

amount of thread extending outboard beyond the

nut is approximately equal on both ends.

4. Tighten the nuts to the torque values shown

in Table 5 following the designated sequence,

repeating the sequence as shown. Flange pattern

tightening sequences are shown in Figure 4.

Bolt Lubrication

Lubrication will affect required torque of clean

fasteners in good condition more than any other factor.

In fact, 90% of applied torque goes to overcome

friction while only 10% actually stretches the bolt.

Table 5 assumes that only machine oil is used as a

lubricant. Table 6 shows a list of several common

lubricants and their effect on torque required to stretch

bolts to 50% of their yield strength. Most are available

from local bearing distributors.